Share Group Limited

Introduction:

SHARE GROUP LIMITED (hereinafter short for SHARE) is an enterprise set up in 1983, producing and supplying filter

fabrics back then. After more than 30 years of fast development,

SHARE has successfully developed and evolved into a big group

company owning three production units, producing Filter Clothes, Printing Mesh and Plastic Filter Parts separately, however, Sales, After-service and Accounting are

maintained and operated under the name of SHARE.

What SHARE offers:

- Industrial Filter Fabrics: Polyester Filter Cloth, Polyamide Filter Cloth, Polypropylene

Filter Cloth, Airslide Fabrics, Polyester Filter Mesh,

Polypropylene Filter Mesh, Nylon Filter Mesh, Stainless Steel

Filter Mesh, Dust Collection and Liquid Filtration Felts and

various kinds of Standard and Customized Liquid Filter Bags, Dust

Collector Filter Bags made of Filter Mesh, Filter Cloth and Filter

Felts.

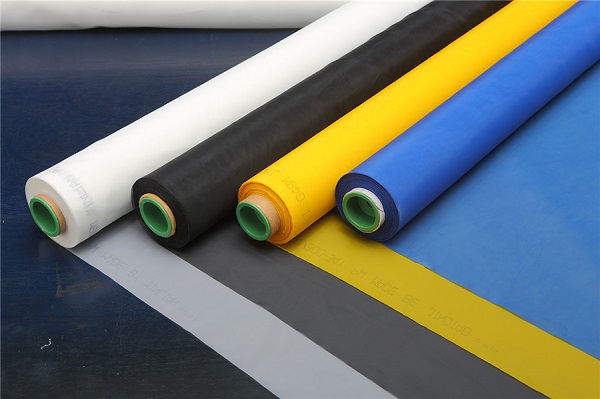

- Silk Printing Mesh: Mono-filament Polyester Printing Mesh, Multifilament Polyester

Printing Mesh, Nylon Printing Mesh, Stainless Steel Printing Mesh

- Molded Filters: Insert/Over-molded Plastic Filters, Rubber-molded Filters

Where SHARE products applied:

- Industrial Filtration: Automotive, Chemical Processing, Cooking Oil/Food Processing,

Ethanol, Mining Operation, Municial Waterworks, Oil and Gas, Power

Plants, Pulp and Paper Mills, Vehicle Washing Systems.

- Silk Printing: Electronic (Printed Circuits, Membrane Swtiches and Dials, Touchscreen and

Displays), Glass, Graphics, Plastics and Packaging, Textiles, Ceramic and

Tiles Industry, Solar.

How to contact SHARE:

- By Phone: +86 (Country Code)-576-8950 8685

- By Fax: +86 (Country Code)-576-8543 2410

- By Email: sales@sharefilters.com or eric@sharefilters.com

- By Submitting Online Inquiry: Send Inquiry

- By Instant Message (The fastest and most convenient means):

Skype: sharefilters - By Simple Contact Form: Simply submitting your general inquiries or questions by

submitting the contact form from left sidebar, we will come back to

you as soon as we can.

Customer Services:

SHARE always believes that selling products is not the end of the sales

process, successful sales includes smooth pre-sale communication,

supply of quality products and excellent after-sales customer

service; By adhering to the corporate pholosophy " Quality is the flesh of the corporate, while Customer Satisfcation

is the blood " ; By working with SHARE, you will get more than just the quality

products at competitive price, you will get the best customer

service.

If you need any customer service, please contact SHARE by either way listed above or simply write to us: service@sharefilters.com