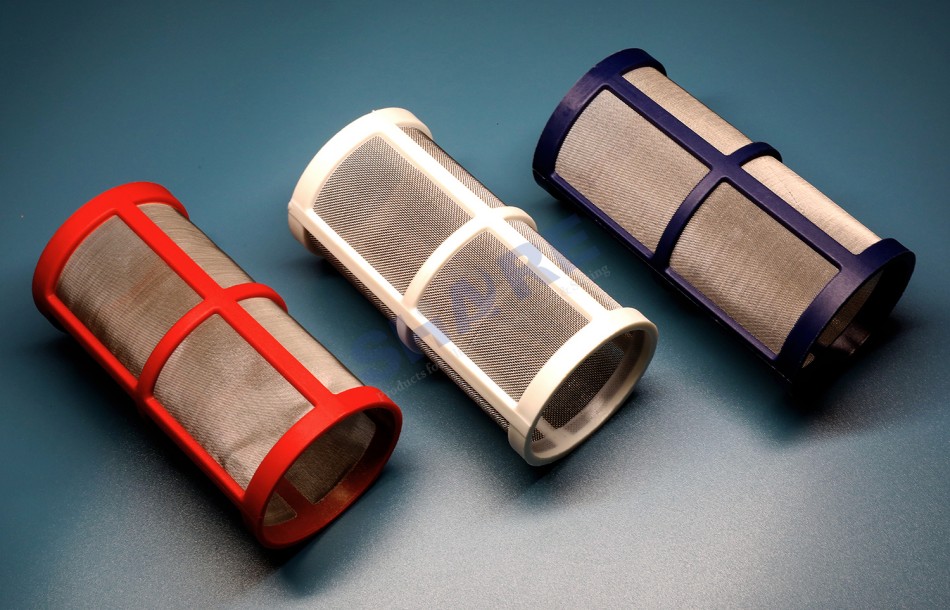

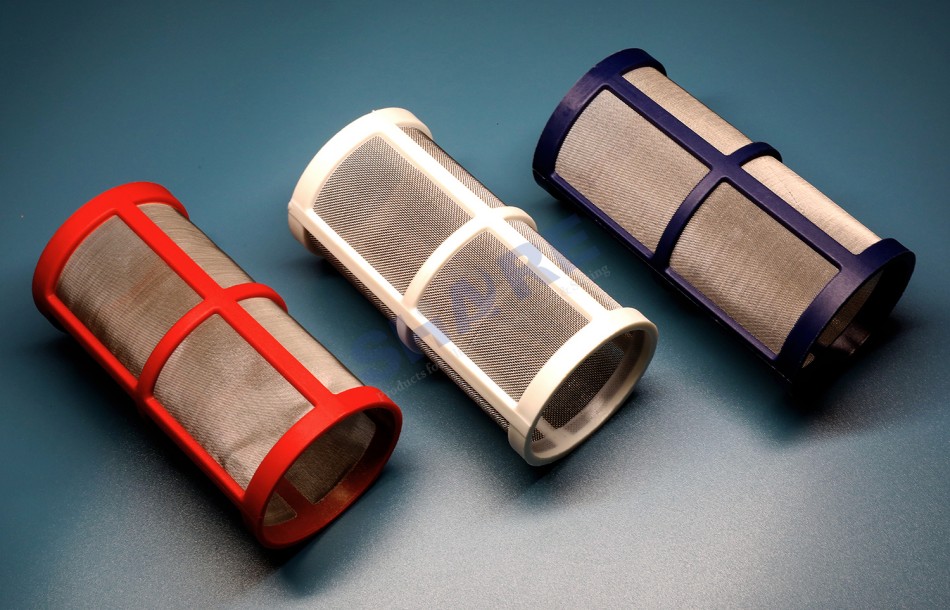

Cylindric Stainless Steel Filtering Element For Pressure Gearbox

The primary purpose of the filter is to prevent debris, such as

metal shavings, dirt, and other particles, from circulating within

the gearbox. These contaminants can cause wear and tear on the

gearbox components, leading to reduced performance, increased

friction, and potential damage.

The cylindric stainless steel filtering element for pressure gearbox has several important functions:

- Sediment Removal

- Protecting Equipment

- Improving Performance

- Extending Maintenance Intervals

Share Filters' injection stainless steel filtering element for pressure gearbox consist of a nylon or polyester filter mesh held in a polymer

plastic frame, allowing for a more robust part giving more

reliability and longevity in its use. Injection moulding can take

many forms and Share Filters is fully capable to help develop and

produce the injection moulded filter product that will best suit

our customers' needs, as well as, offering any additional advice or

service along the way.

Injection Moulding Process

Injection moulding can provide a part or product that carries a

more complex shape for more specific functionality, as well as,

still being cost-effective and able to be produced in larger

numbers consistently and within a deadline.

Other OEM Mesh Insert Injection Molded Plastic Filters

Share Filtes Plastic Moulded Materials Options

| Support rim material | PA6, PA66, PET, PP, ABS, POM, and other high- performance

thermoplastics |

| Filter media | Nylon mesh, polyester mesh, PP mesh, stainless steel mesh, brass

mesh |

| Micron rating | 3μm - 3233μm |

| Mesh parts fabrication | Slitting, cutting, sonic welding |

| Process method | Mesh insert injection moulding |

| Specification | Custom |

| Colour | Custom |

How to select the right filter mesh? You can follow these points.

| - Mesh size or the size of the particle you need to filter

- Mesh material (consider the working condition)

- Mesh thread diameter, Mesh thickness

- Opening area

|

Stainless Steel Wire Mesh Specification

| Mesh | Wire Dia. (MM) | Opening (MM) | Material (AISI) |

| 7meshx7mesh | 1.00 | 2.63 | 304 or316 |

| 10meshx10mesh | 0.60 | 1.94 | 304 or316 |

| 12meshx12mesh | 0.50 | 1.62 | 304 or316 |

| 16meshx16mesh | 0.40 | 1.19 | 304 or316 |

| 16meshx16mesh | 0.35 | 1.24 | 304 or316 |

| 18meshx18mesh | 0.35 | 1.06 | 304 or316 |

| 20meshx20mesh | 0.40 | 0.87 | 304 or316 |

| 24meshx24mesh | 0.26 | 0.80 | 304 or316 |

| 30meshx30mesh | 0.30 | 0.55 | 304 or316 |

| 35meshx35mesh | 0.17 | 0.56 | 304 or316 |

| 40meshx40mesh | 0.23 | 0.40 | 304 or316 |

| 50meshx50mesh | 0.20 | 0.31 | 304 or316 |

| 60meshx60mesh | 0.15 | 0.27 | 304 or316 |

| 70meshx70mesh | 0.12 | 0.24 | 304 or316 |

| 80meshx80mesh | 0.13 | 0.19 | 304 or316 |

| 90meshx90mesh | 0.12 | 0.16 | 304 or316 |

| 100meshx100mesh | 0.10 | 0.15 | 304 or316 |

| 120meshx120mesh | 0.09 | 0.12 | 304 or316 |

| 150meshx150mesh | 0.063 | 0.11 | 304 or316 |

| 180meshx180mesh | 0.053 | 0.09 | 304 or316 |

| 200meshx200mesh | 0.053 | 0.07 | 304 or316 |

This data sheet just include our common specification, please

contact us if you have other custom specification

Properties of Thermoplastic

PA6 (polyamide 6) Tough, abrasion-resistant, good vibration damping,

resistant to solvents, fuels and lubricant

PA66 (polyamide6.6) Rigid, stiff, abrasion-resistant, dimensionally

stable at heat exposure.

PET (polyethyleneterehthalate) High rigidity, high hardness, high

chemical resistance, good dimensional stability.

PP (polypropylene) Good chemical resistance, more heat resistant than

PVC

PEEK (polyetheretherketone) High mechanical strength, stiffness,

toughness, temperature, chemical and radiation resistance

Share Filters Factory Facilities

| Synthetic Mesh | Slitting | Cutting | Welding | Sewing | Injection Moulding |

|  |  |  |  |  |

| Share Filters synthetic meshes can be made from a variety of

materials such as polyamide, polyester, polypropylene, etc. You can

order by the roll or cut shape. | Ultrasonic slitting is also used for manufacturing fabric strips

and produces a closed edge with very little material build up at

the edge. | Our cutting method include Laser cutting, Cold cutting, Hot

cutting, Slitting, Stamping. Professional cutting using custom made

tools that will not damage the materials. | Sonic welding are accurate, clean. Precision sleeves and bags for

blood filtration, rosin bag for rosin press are examples of

applications that benefit from this technology. | Share Filters sewing products are carried out by highly skilled and

experienced machinists, which ensure you get the right level of

consistent quality. | Custom plastic molded filter combine precise filter mesh with

polymer plastic. Industry serve: Automotive, Appliances, Food and

beverage, Medical, Life Science and Laboratory. |

About Share Filters

Share Filters has over 20 years of experience developing and

manufacturing filter meshes and solutions for our customer's screen

and filtration needs. Many of our custom filters products are

molded from mesh and plastic, utilizing our insert injection

molding or pot molding capabilities. These processes allow for

flexibility in design and material selection. They also offer

significant advantages in cost and ease of manufacture over other

potential solutions.

Share Filters Products Applications

|  |  |  |  |  |

| Automotive | Appliance | Medical | Food & Beverage | Chemical | Environmental |