Inlet Fuel Top Feed Injector Micro Filter Basket Size 6×3×10mm

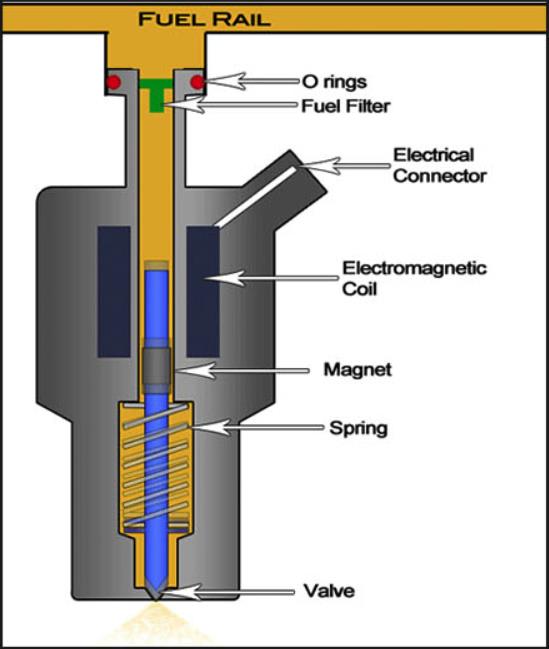

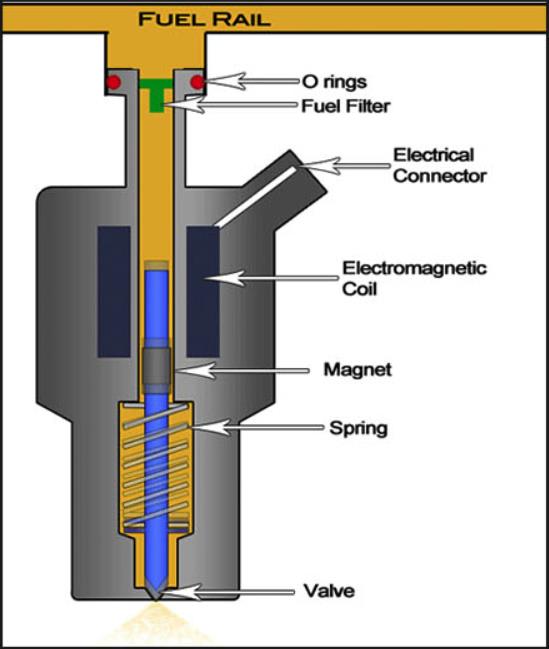

The fuel injector filter is a component in fuel injection systems

of internal combustion engines. Its function is to prevent

contaminants and debris from entering the fuel injector and

clogging it. The injector filter is typically a small mesh screen

or filter element that is situated at the inlet of the fuel

injector. Share Filters injector filter protects the injection valves from damage and

malfunction and ensures reliable operation of the injection system.

Fine woven fabrics and a clamping ring ensure reliable particle

protection and optimum fixation.

Share Filters' injector filters consist of a nylon or polyester

filter mesh held in a polymer or brass frame by insert moulding,

allowing for a more robust part giving more reliability and

longevity in its usage. This injection moulding processing can take

many forms and Share Filters is fully capable to help develop and

produce the injection moulded filter product that will best suit

your needs, as well as, offering any additional advice or service

along the way.

Share Filtes Injector Filters Materials Options

| Support rim material | PA6, PA66, PET, PP, ABS, brass, and other High-Performance

Thermoplastics |

| Filter media | Nylon mesh, polyester mesh, PP mesh, metallic mesh |

| Micron rating | 8μm - 500μm |

| Mesh parts fabrication | Laser cutting, sonic cutting, sonic stamping |

| Process | Injection moulding |

| Specification | ø6*7, 6*10, 6*12, 6*14, 5.5*8.5mm, ect. |

| Colour | Custom |

Product Details

The Feature of Share Filters Fuel Injector Filters

- Filter media in PA, PE, and stainless steel to offer different flow

capacities according to the specifications required

- Filter macron rating range between 8 and 300 micron

- High filter surface, even in extremely small volumes, respecting

the specifications or increasing the performance

- Quality and experience acquired in the sector enable innovative

solutions

Other Fuel Injector Filters

Properties of Polymer

| Material | PA6 | PA66 | PET | PP | PEEK |

| Specific gravity (g/mm²) | 1.14 | 1.14 | 1.38 | 0.91 | 1.30 |

| Tensile strength(daN/mm²) | 41-67 | 41-67 | 45-75 | 35-62 | 33-75 |

| Relative strength at wet conditions(%) | 89-90 | 85-90 | 100 | 100 | 100 |

| Elongation at break (%) | 20-35 | 20-35 | 15-30 | 20-50 | 20-40 |

| Moisture absorption at 20°C / 65% r.h. (%) | 3.5-4 | 3.5-4 | 0.4 | 0 | 0.1 |

| Melting point (°C) | 210-220 | 260-268 | 250-260 | 165-175 | 334 |

| Softening point (°C) | - | - | 220-240 | 140-155 | 300 |

| Working temperature dry (°C) | - | - | -75 to +150 | -30 to +90 | up to 250 |

| Stability to light | poor | poor | poor | poor | good |

| Atmospheric influence | - | - | none | none | none |

| Abrasion resistance | good | good | limited | limited | good |

| Acid resistance | limited-poor | limited-poor | good | good | good |

| Alkaline resistance | good | good | limited | good | good |

| Stability to solvents | limited | limited | good | good | good |

| Hydrolysis resistance | good | good | limited | good | good |

How To Select The Right Filter Mesh? You Can Follow These Points

- Pore size or the size of the particle you need to filter

- Mesh material (consider the working condition)

- Mesh thread diameter, mesh thickness

- Opening area

|  |

PA(nylon) Filter Mesh Specification

| Ref. No. | Mesh Count | Thread Diam. | Mesh Opening | Opening Area |

| mesh/cm | mesh/inch | µm | µm | % |

| JPP12 | 12 | 30 | 250 | 583 | 49 |

| JPP12 | 12 | 30 | 300 | 533 | 41 |

| JPP14 | 14 | 35 | 300 | 414 | 34 |

| JPP16 | 16 | 40 | 200 | 425 | 46 |

| JPP16 | 16 | 40 | 250 | 375 | 36 |

| JPP20 | 20 | 50 | 150 | 350 | 49 |

| JPP20 | 20 | 50 | 200 | 300 | 36 |

| JPP24 | 24 | 60 | 150 | 267 | 41 |

| JPP28 | 28 | 70 | 120 | 237 | 44 |

| JPP30 | 30 | 76 | 120 | 213 | 41 |

| JPP32 | 32 | 80 | 100 | 213 | 46 |

| JPP36 | 36 | 90 | 100 | 178 | 41 |

| JPP40 | 40 | 100 | 100 | 150 | 36 |

| JPP43 | 43 | 110 | 80 | 152 | 43 |

| JPP48 | 48 | 120 | 80 | 130 | 38 |

| JPP56 | 56 | 140 | 60 | 120 | 44 |

| JPP59 | 59 | 150 | 60 | 110 | 42 |

| JPP64 | 64 | 160 | 60 | 100 | 37 |

| JPP72 | 72 | 180 | 50 | 90 | 41 |

| JPP80 | 80 | 200 | 50 | 75 | 36 |

| JPP100 | 100 | 250 | 40 | 60 | 36 |

| JPP120 | 120 | 305 | 40 | 43 | 25 |

| JPP130 | 130 | 330 | 40 | 37 | 23 |

| JPP140 | 140 | 355 | 30 | 38 | 33.7 |

| JPP150 | 150 | 381 | 30 | 34 | 30.25 |

| JPP165 | 165 | 420 | 30 | 28 | 20.7 |

| JPP180 | 180 | 460 | 30 | 25 | 19.5 |

| JPP200 | 200 | 510 | 30 | 20 | 10.2

|

This data sheet just include our common specification, please

contact us if you have other custom specification

About Us

Share Filters has over 20 years of experience developing and

manufacturing filter mesh and solutions for our customer's screen

and filtration needs. Our monofilament filter mesh includes nylon

mesh, polyester mesh, polypropylene mesh, stainless steel mesh.

Thanks to the advanced processing equipments and extensive

experience, Share Filters has the capability to convert these

filter media into all kinds of mesh shapes, discs, ribbons, tubes,

bags and plastic moulded filters.

Many of our custom filter products are moulded from mesh and

plastic, utilizing our insert injection molding or pot molding

capabilities. These processes allow for flexibility in design and

material selection. They also offer significant advantages in cost

and ease of manufacture over other potential solutions.

Factory Capabilities

|  |  |

| Share Filter synthetic meshes can be made from a variety of

materials such as polyamide, polyester, polypropylene, etc. You can

order by the roll or cut shape. | Slitting is also used for manufacturing mesh strips and produces a

closed edge with very little material build up at the edge. | Our cutting method include Laser cutting, Cold cutting, Heatt

cutting, punching. Professional cutting using custom made tools

that will not damage the materials. |

|  |  |

| Sonic cutting and welding are accurate, clean. Precision sleeves

and bags for blood filtration, rosin bag for rosin press are

examples of applications that benefit from this technology. | Share Filters sewing products are carried out by highly skilled and

experienced machinists, which ensure you get the right level of

consistent quality. | Custom plastic moulded filter combine precise filter mesh with

polymer plastic. Industry serve: Automotive, Appliances, Food and

beverage, Medical, Life Science and Laboratory.

|

Share Filters Products Applications

|  |  |  |  |

| Automotive | Appliance | Health care | Food & Beverage | Chemical |

Contact Us

Share Filters provides some information for filter mesh possible

applications, but there are too many functions for comprehensive

descriptions of possible uses. Therefore, when considering a

potential application in your particular industry, please consider

contacting us who will work with engineers and product designers in

choosing the right material and process for your specific projects.

Packing and Transportation