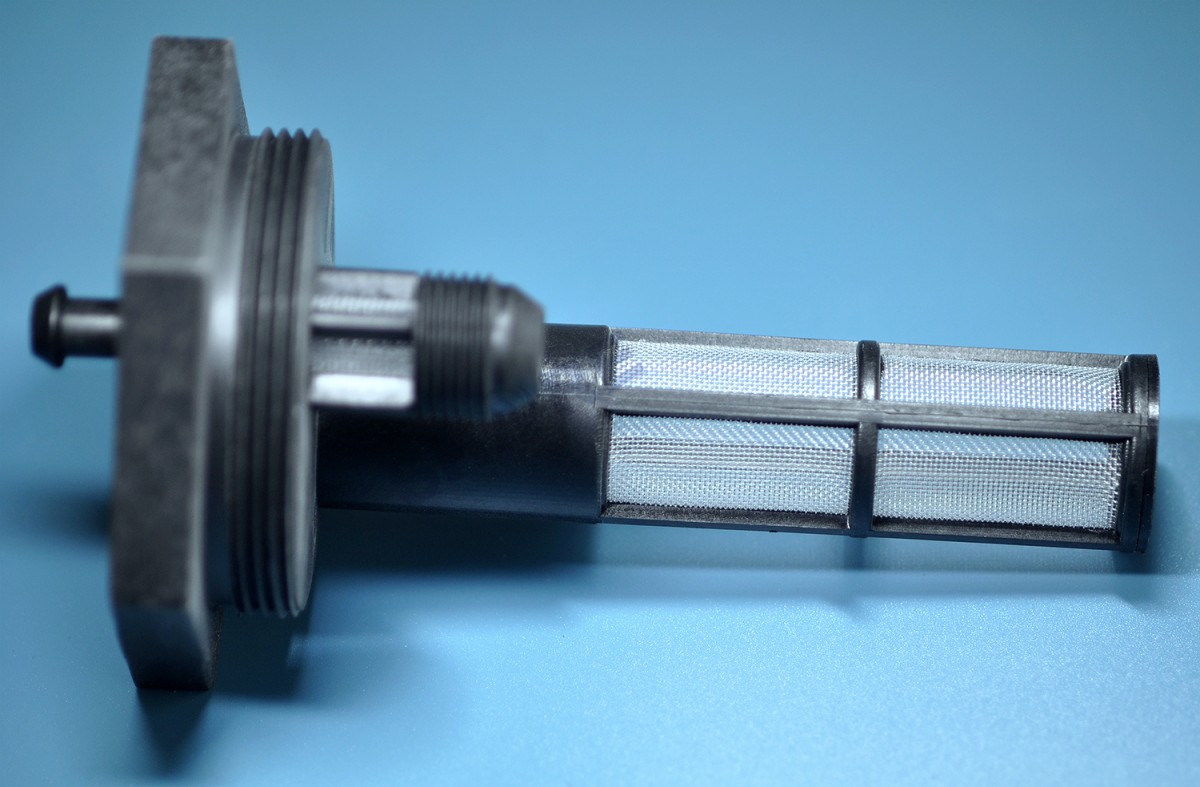

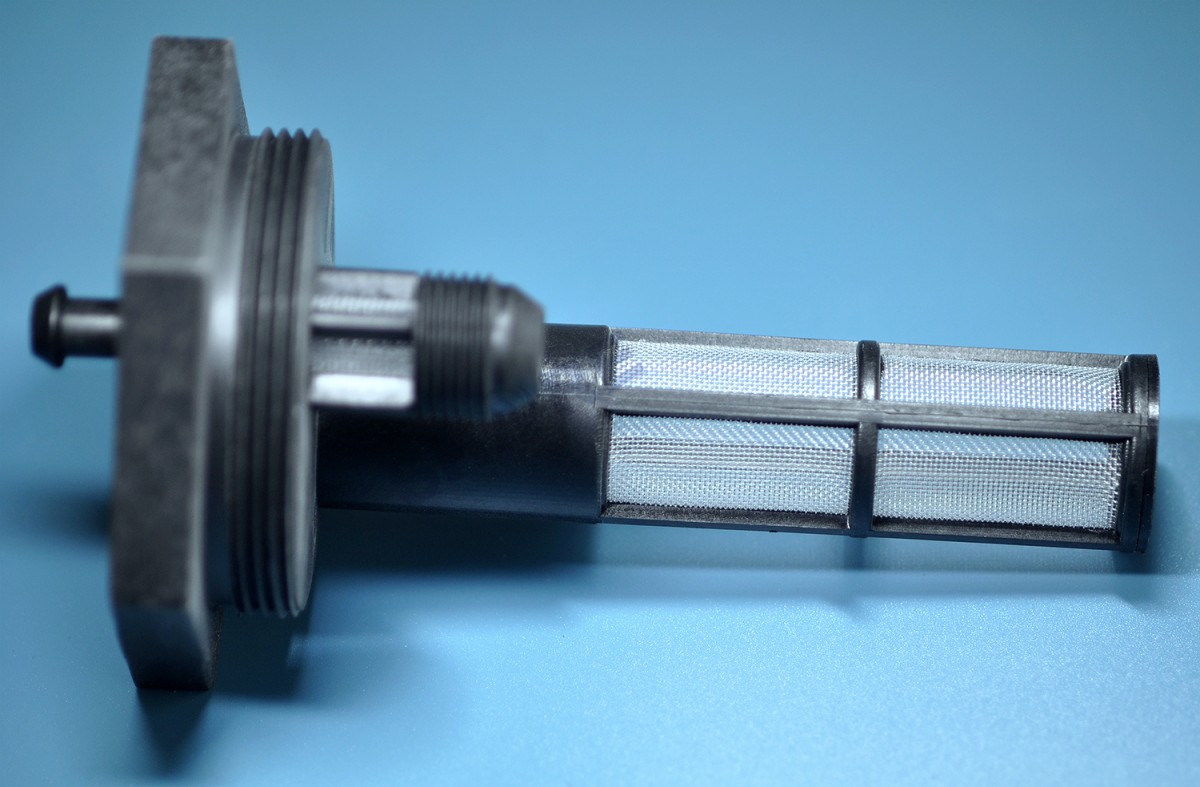

Foaming Dispenser Filter Two Sides Mesh Screen 8.5x13mm for Liquid

Foam Pump Generator

The foam pump screen, also known as foam generator screen, is a

component used in foaming dispensers or foam pumps to create rich

and luxurious foam from liquid soap or other foaming products, for

example: sanitizer, facial cleanser, bath cream. It is typically a

small, cylindrical or disc-shaped screen made of plastic or metal

with mesh discs.

Share Filters' custom foam generator screen is a small cylindrical

screen, it consists of a nylon or polyester filter mesh held in a

pp tube, allowing for a more robust part giving more reliability

and longevity in its usage. This injection moulding processing can

take many forms and Share Filters is fully capable to help develop

and produce the injection moulded filter product that will best

suit your needs, as well as, offering any additional advice or

service along the way.

Share Filters Foam Generator Screen Materials Options

| Rim frame material: | PA6, PA66, PET, PP, ABS, and other thermoplastics |

| Mesh screen: | Nylon mesh, polyester mesh, PP mesh, metallic mesh |

| Micron rating: | 50μm - 500μm |

| Mesh parts fabrication: | Cutting, punching |

| Processing: | Insert injection molding, over molding |

Product Pictures

Customization

We can also use other colors or materials instead of our available

versions on request. If the desired dimensions of the plastic parts are not included in

our range, we can customize the products according to your

specifications.

Bebefits From Share Filters' OEM Plastic Filters:

Nylon Filter Mesh Specification for Foam Pump Screen

| Fabric Number | Mesh Count | Thread Diameter | Mesh Opening | Open Area | Mesh Thickness | Weight |

|

| | n/cm | n/inch | μm | μm | % | μm | g/m2 |

| PA 583/49 | 12 | 30 | 250 | 583 | 49 | 470 | 162 |

| PA 533/41 | 12 | 30 | 300 | 533 | 41 | 585 | 234 |

| PA 414/34 | 14 | 35 | 300 | 414 | 34 | 595 | 273 |

| PA 425/46 | 16 | 40 | 200 | 425 | 46 | 370 | 139 |

| PA 375/36 | 16 | 40 | 250 | 375 | 36 | 485 | 217 |

| PA 350/49 | 20 | 50 | 150 | 350 | 49 | 375 | 98 |

| PA 300/36 | 20 | 50 | 200 | 300 | 36 | 385 | 173 |

| PA 267/41 | 24 | 60 | 150 | 267 | 41 | 285 | 117 |

| PA 237/44 | 28 | 70 | 120 | 237 | 44 | 215 | 87 |

| PA 213/41 | 30 | 76 | 120 | 213 | 41 | 225 | 94 |

| PA 213/46 | 32 | 80 | 100 | 213 | 46 | 165 | 69 |

| PA 178/41 | 36 | 90 | 100 | 178 | 41 | 178 | 78 |

| PA 150/36 | 40 | 100 | 100 | 150 | 36 | 190 | 87 |

| PA 152/43 | 43 | 110 | 80 | 152 | 42 | 135 | 60 |

| PA 130/38 | 48 | 120 | 80 | 130 | 38 | 145 | 62 |

| PA 120/44 | 56 | 140 | 60 | 120 | 44 | 85 | 44 |

| PA 110/42 | 59 | 150 | 60 | 110 | 41 | 98 | 46 |

| PA 100/37 | 64 | 160 | 60 | 100 | 38 | 105 | 50 |

| PA 90/41 | 72 | 180 | 50 | 90 | 41 | 82 | 39 |

| PA 75/36 | 80 | 200 | 50 | 75 | 36 | 90 | 43 |

| PA 60/36 | 100 | 250 | 42 | 60 | 34 | 65 | 35 |

| PA 42/25 | 120 | 305 | 42 | 42 | 24 | 75 | 42 |

| PA 44/27 | 120 | 305 | 38 | 44 | 29 | 72 | 35 |

| PA 42/25 | 120 | 305 | 38 | 42 | 25 | 67 | 35 |

| PA 45/29 | 120 | 305 | 35 | 45 | 33 | 60 | 28 |

| PA 55/42 | 120 | 305 | 30 | 55 | 40 | 52 | 20 |

Other OEM Mesh Filter

How To Select the Right Filter Mesh? You Can Follow These Points:

| - Mesh size or the size of the particle you need to filter

- Mesh material (consider the working condition)

- Mesh thread diameter, Mesh thickness

- Opening area

|

Taizhou Share Filters, An OEM Mesh Insert Molded Filters

Manufacture From China

As a filter meshes and plastic moulded filters manufacture, Share

Filters always find the best solution is to work with our OEM

customers to collaborate on their mesh filtration product

development projects before the final design prints are completed.

Our experienced engineers are able to not only to meet your

functional requirements, but also to recommend materials to improve

performance and manufacturability. We will concentrate on the

following:

Factory Capabilities

Share Filters specializes in helping our customers design and

manufacture high quality mesh filter components to around the

world. As a supplier combining the woven filter mesh manufacturing

and filter mesh processing according to custom-made design, we are

more flexible h to adapt to our customers’ production and delivery

needs. Our advanced manufacturing processes and scientific machines

allow us to create mesh filters in any shape or configuration –

from simple components like mesh shapes and filter bags to highly

complex devices like custom plastic moulded filters.

|  |  |

| Share Filter synthetic meshes can be made from a variety of

materials such as polyamide, polyester, polypropylene, etc. You can

order by the roll or cut shape. | Slitting is also used for manufacturing mesh strips and produces a

closed edge with very little material build up at the edge. | Our cutting method include Laser cutting, Cold cutting, Heatt

cutting, punching. Professional cutting using custom made tools

that will not damage the materials. |

|  |  |

| Sonic cutting and welding are accurate, clean. Precision sleeves

and bags for blood filtration, rosin bag for rosin press are

examples of applications that benefit from this technology. | Share Filters sewing products are carried out by highly skilled and

experienced machinists, which ensure you get the right level of

consistent quality. | Custom plastic moulded filter combine precise filter mesh with

polymer plastic. Industry serve: Automotive, Appliances, Food and

beverage, Medical, Life Science and Laboratory. |

Contact Us

Share Filters provides some information for filter mesh possible

applications, but there are too many functions for comprehensive

descriptions of possible uses. Therefore, when considering a

potential application in your particular industry, please consider

contacting us who will work with engineers and product designers in

choosing the best products for your specific projects.