Photos of Factory

|

| Warping | Weaving | Inspection |

|

| Whashing | Heat setting | Ultrasonic welding, cutting |

Packing and Transportation

Share Filters offers different kinds of shipping, we can deliver

the goods in different method depends on your order quantity.

- Small volume order, you can choose UPS, TNT, DHL, FedEx, EMS

- Large quantities is better by sea which is cost economic. Sometimes

by air if urgent in need.

- SF EXPRESS usually to Hongkong and Southeast Asia countries.

- Samples are always sent via express commonly.

Contact Us

Share Filters provides some information for filter mesh possible

applications, but there are too many functions for comprehensive

descriptions of possible uses. Therefore, when considering a

potential application in your particular industry, please consider

contacting us who will work with engineers and product designers in

choosing the right material and processing for your specific

projects.

Please connect with us now so we can learn more about your

application and design specifications!

FAQ

Are You Factory or Trade Company ?

We're factory, and manufacture our products in-house.

Where Is Your factory Located? How Can I Get There?

We are in Tiantai city, Zhejiang province China. By train, one hour

away from Hangzhou and two hours away from Shanghai.

Which Port You Ship?

Ningbo port.

Can I Get Free Samples ?

We are pleased to provide you with free samples for testing, just

the freight will be at your account.

What's Your Payment Term ?

T/T, LC, PayPal, and others.

What's the Lead Time of the Order?

The production lead time is dependent on the quantity. It takes 5

to 20 working days for us to complete mass production after receive

the payment.

What About Your Quality Control?

By visual inspection, optical or pressure sensitive equipment and

automated 3D image-inspection equipment, our production operators

conduct self-inspections at every stage of the process, from the

raw material to finshed products. Additionally, we have spot

inspections and final inspections carried out by our QC team.

Why Choose You ?

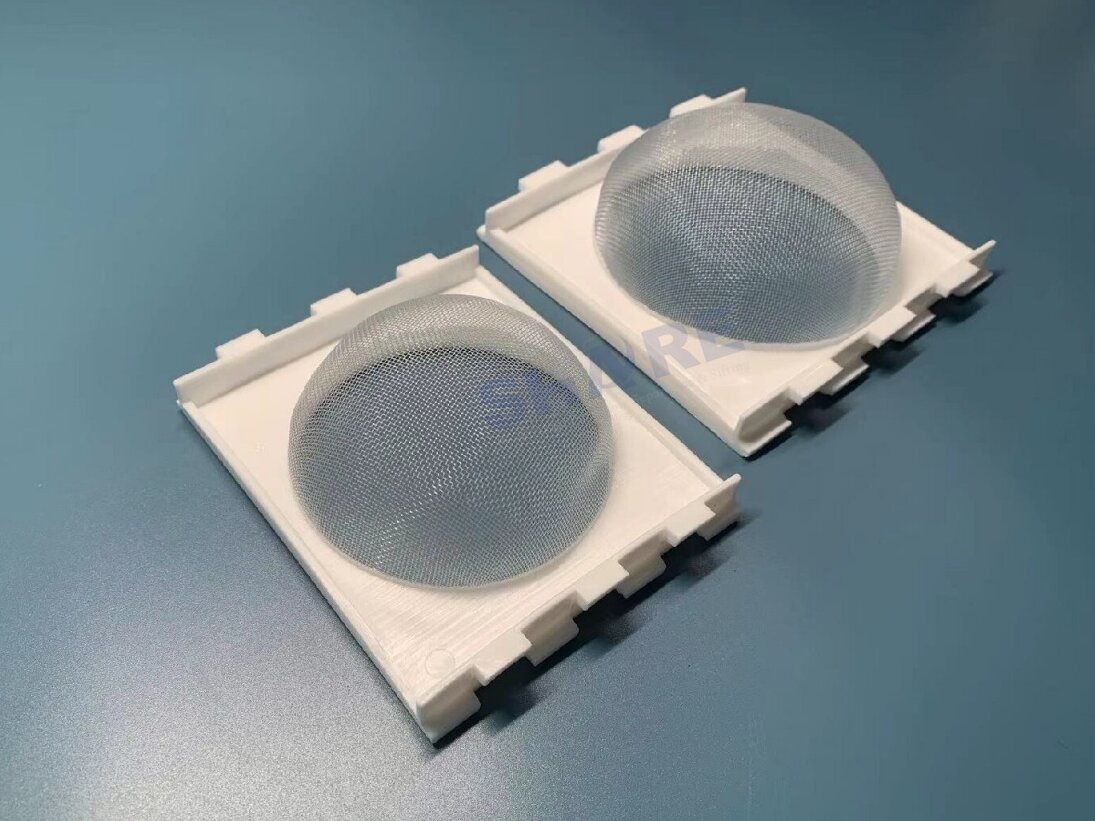

One of our core competencies is our excellent processing

capabilities, convert the woven filter mesh to mesh ribbons, discs,

shapes, tubes, bags, plastic moulded filters, with advanced

equipments and professional technical team for more than 20 years.

We're the few supplier who have experience with synthetic filter

meshes and are able to use them with plastic moulding in good

conditions.

How To Delivery the Order?

Small batch is sent by UPS, Fedex, TNT, DHL, EMS, ect, high volume

will be shipped by sea and air.