Abrasion Resistant Nylon Filter Mesh For Powder Filtration In Food

Industry

Share Nylon filter mesh is highly suitable for powder filtration

applications in the food industry. The application of nylon filter mesh in powder filtration

contributes to higher product quality by ensuring that the powder

is free from unwanted elements that could impact taste, appearance,

or texture. It helps maintain the desired standards and

specifications for the end product. When used for filtering powders such as flour, powdered sugar,

cocoa powder, and other fine powders, it offers several benefits:

- Particle removal: Nylon filter mesh effectively traps and removes

particles of various sizes from the powder. It can capture both

large and small particles, ensuring that the final product is free

from unwanted contaminants.

- Fiber separation: In some powders, there may be fibers present that

can affect the texture and quality of the end product. Nylon filter

mesh with the appropriate mesh size can efficiently separate and

remove these fibers, resulting in a smoother and more refined

powder.

- Impurity elimination: Powders can sometimes contain impurities or

foreign matter that need to be eliminated. Nylon filter mesh acts

as a barrier, preventing impurities from passing through, and

ensuring a cleaner and purer final product.

- Consistency and uniformity: By removing particles, fibers, and

impurities, nylon filter mesh helps achieve a consistent and

uniform powder texture. This is particularly important in

applications where the powder's appearance, texture, and flow

properties are crucial, such as in baking, confectionery, and

beverage production.

Nylon Filter Mesh Specification Options

| Yarn | Monofilament (Single Filament), Multi-filament |

| Yarn Diameter | From 30 micron to 1000 micron |

| Mesh Opening | From 3 micron to 2000 micron |

| Open Area | From 10% to 60% |

| Weave Type | Plain Weave, Twill Weave and Satin Weave |

| Treatment | Washing, Heat-setting, Calendaring, Water-repellent |

| Size | Can slit or cut in custom dimension |

Nylon filter mesh is available in various mesh sizes, allowing for

customization based on the specific requirements of the powder

filtration process. The mesh size determines the level of

filtration precision, ensuring that the desired particles, fibers,

and impurities are effectively removed while maintaining the

desired powder characteristics.

The Benefit Features of Nylon Filter Mesh:

| High tensile strength

Abrasion resistant

Resistance to alkali

Precise and even mesh opening

Light weight

Elasticity and flexibility

Temperatures up to 100°C

Hydrophilic

Soft, smooth feeling

Easy cutting, dyeing, and cleaning |

Nylon Filter Mesh Product Datasheet

| Ref. No. | Mesh Count | Thread Diam. | Mesh Opening | Opening Area |

| mesh/cm | mesh/inch | µm | µm | % |

| JPP5 | 5 | 12 | 500 | 1500 | 56 |

| JPP6 | 6 | 16 | 400 | 1267 | 58 |

| JPP7 | 7 | 18 | 350 | 1079 | 57 |

| JPP8 | 8 | 20 | 350 | 900 | 52 |

| JPP9 | 9 | 24 | 250 | 860 | 60 |

| JPP10 | 10 | 25 | 300 | 700 | 49 |

| JPP12 | 12 | 30 | 250 | 583 | 49 |

| JPP12 | 12 | 30 | 300 | 533 | 41 |

| JPP14 | 14 | 35 | 300 | 414 | 34 |

| JPP16 | 16 | 40 | 200 | 425 | 46 |

| JPP16 | 16 | 40 | 250 | 375 | 36 |

| JPP20 | 20 | 50 | 150 | 350 | 49 |

| JPP20 | 20 | 50 | 200 | 300 | 36 |

| JPP24 | 24 | 60 | 150 | 267 | 41 |

| JPP28 | 28 | 70 | 120 | 237 | 44 |

| JPP30 | 30 | 76 | 120 | 213 | 41 |

| JPP32 | 32 | 80 | 100 | 213 | 46 |

| JPP36 | 36 | 90 | 100 | 178 | 41 |

| JPP40 | 40 | 100 | 100 | 150 | 36 |

| JPP43 | 43 | 110 | 80 | 152 | 43 |

| JPP48 | 48 | 120 | 80 | 130 | 38 |

| JPP56 | 56 | 140 | 60 | 120 | 44 |

| JPP59 | 59 | 150 | 60 | 110 | 42 |

| JPP64 | 64 | 160 | 60 | 100 | 37 |

| JPP72 | 72 | 180 | 50 | 90 | 41 |

| JPP80 | 80 | 200 | 50 | 75 | 36 |

| JPP100 | 100 | 250 | 40 | 60 | 36 |

| JPP120 | 120 | 305 | 40 | 43 | 25 |

| JPP130 | 130 | 330 | 40 | 37 | 23 |

| JPP140 | 140 | 355 | 30 | 38 | 33.7 |

| JPP150 | 150 | 381 | 30 | 34 | 30.25 |

| JPP165 | 165 | 420 | 30 | 28 | 20.7 |

| JPP180 | 180 | 460 | 30 | 25 | 19.5 |

| JPP200 | 200 | 510 | 30 | 16 | 10.2 |

Share has over 20 years of experience developing and manufacturing

filter mesh and custom product solutions for our customer's screen

and filtration needs. We can offer the filter meshes and filter

components processing including slitting, cutting, punching,

welding, sewing and mesh insert injection molding.

Nylon Filter Mesh in Rolls

The width of nylon filter mesh rolls can be in 100cm, 127cm, 150cm,

160cm, 175cm, 183cm, 365cm or

other custom width.

Length can be 30m, 50m, 70m, or other custom length.

Nylon Filter Mesh in Narrow Strips

Share Filters ultrasonic slitting is also used for manufacturing

fabric strips and produces a closed edge with

very little material build up at the edge.

Nylon Filter Mesh in Cutted Shapes.

Our cutting method include Laser cutting, Cold cutting, Hot

cutting, Slitting, Punching. Professional cutting

using custom made tools that will not damage the materials.

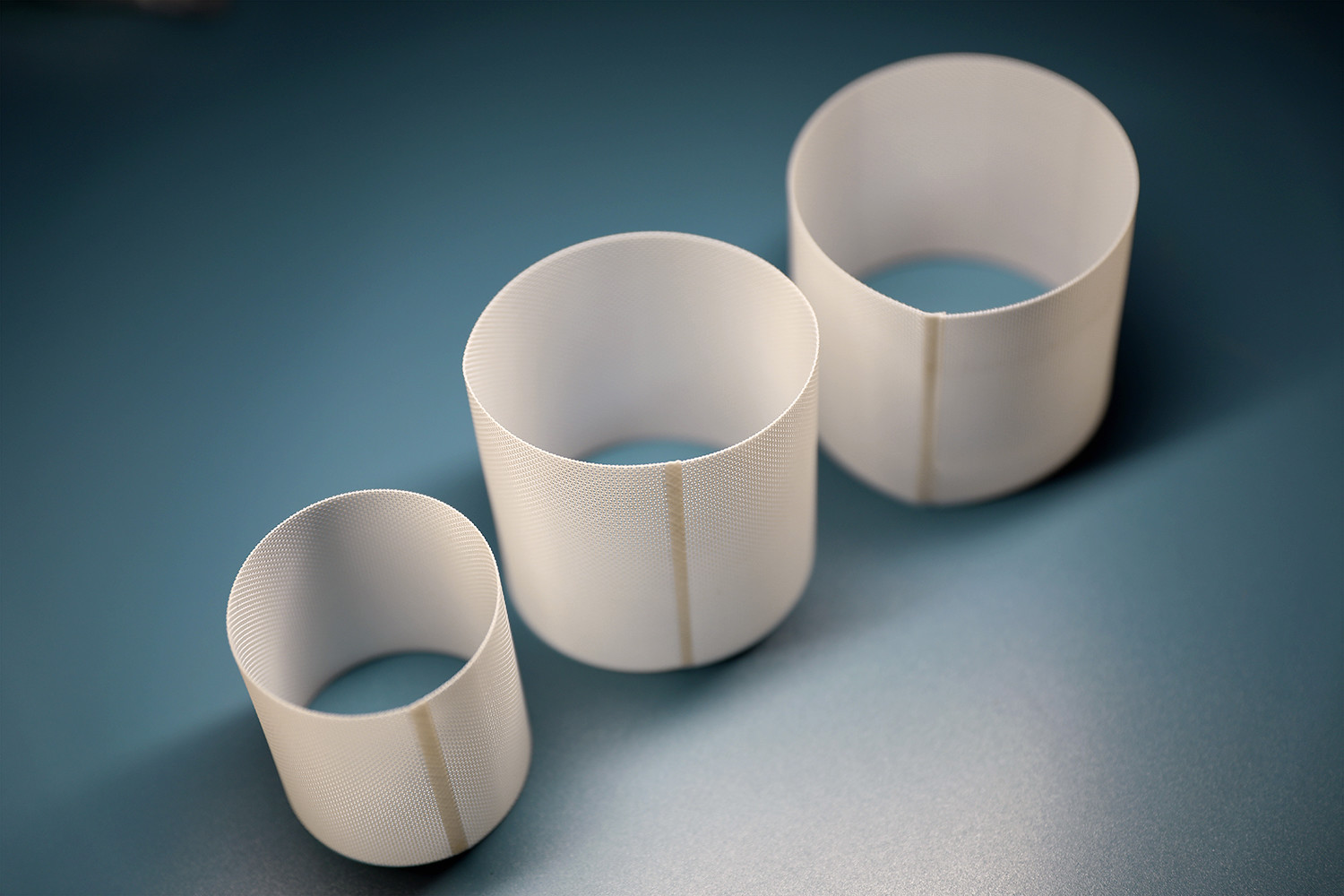

Nylon Filter Mesh In Tubes

Sonic welding are accurate, clean. Lapping welding strength to some

degree.

Custom Nylon Filter Mesh Bags

For liquid food processing filtration operations, Share Filters has

standard filter bags with galvanized steel

or plastic rings, which are sewn or welded, made of regenerable monofilament filter

cloth from 3 micron to

2000 microns or felt from 0.5 microns to 200 microns.

Mesh Insert Plastic Injection Molded Filters

Our injection moulded filters products consist of a synthetic

filter mesh held in a polymer plastic frame,

allowing for a more robust part/product giving more reliability and

longevity in its use.

Nylon Filter Mesh Production Process

About Us

Share has over 20 years of experience developing and manufacturing

filter mesh and custom product solutions for our customer's screen and filtration needs. We can offer the

filter mesh and filter components services including slitting, cutting, welding, sewing and injection molding. Our

customer base comes from a wide variety of industriesincluding – Automotive, Home appliances, Food and beverage,

Milling, Medical, Life Science and laboratory, Electronical as well as more general engineering, giving us a

wealth of experience in many areas.

Nylon Filter Mesh Application in Industry

|  |  |  |  |  |

| Automotive | Healthcare | Appliance | Food & Beverage | Environment | Chemical |