FDA Nylon Filter Mesh For Vegetable Fruit Juice Filtration Process

50 60 200 300 400 500 Micron

Nylon filter mesh is commonly used in the food and beverage

industry, including for filtering vegetable and fruit juice. It is a popular choice due to its durability, food grade, chemical

resistance, and fine filtration capabilities. Nylon mesh filters

can effectively remove solid particles, pulp, and other unwanted

particles from juice, resulting in a smoother and clearer product.

Share Filters' nylon filter mesh is offen made as the filter

element and filter bags which use in the filtration system for

fruit and vegetable juice.

Nylon Filter Mesh Specification Options for Juice Filtration

| Yarn | Monofilament (Single Filament), Multi-filament |

| Yarn Diameter | From 40 micron to 300 micron |

| Mesh Opening | From 50 micron to 500 micron |

| Open Area | From 25% to 41% |

| Weave Type | Plain Weave, Twill Weave and Satin Weave |

| Treatment | Washing, Heat-setting, Calendaring, Water-repellent |

| Size | Can slit or cut in custom dimension |

| Colour | White, or customize

|

Nylon Filter Mesh Nylon Filter Bag Housing

Nylon Filter Mesh Construction

|

Mesh count (n/cm), (n/in) The mesh count stands for the number of openings per inch.

Mesh opening (w), (μm) The mesh opening w is the distance between two adjacent warp or

weft thread.

Thread diameter (d),( μm) The thread diameter is measured on the thread before weaving.

Open area (%) The percentage of the open are is the sum of all mesh openings as

percentage of the total fabric area |

The Benefit Features of Nylon Filter Mesh:

| High tensile strength Precise and even mesh opening Food grade Elasticity and flexibility Good resistance to alkalis Temperatures up to 100°C Hydrophilic Soft, smooth feeling Easy cutting, dyeing, and cleaning |

Properties of Polymers

| Material | PA6 | PA66 | PET | PP | PEEK |

| Specific gravity (g/mm²) | 1.14 | 1.14 | 1.38 | 0.91 | 1.3 |

| Tensile strength(daN/mm²) | 41-67 | 41-67 | 45-75 | 35-62 | 33-75 |

| Relative strength at wet conditions(%) | 89-90 | 85-90 | 100 | 100 | 100 |

| Elongation at break (%) | 20-35 | 20-35 | 15-30 | 20-50 | 20-40 |

| Moisture absorption at 20°C / 65% r.h. (%) | 3.5-4 | 3.5-4 | 0.4 | 0 | 0.1 |

| Melting point (°C) | 210-220 | 260-268 | 250-260 | 165-175 | 334 |

| Softening point (°C) | - | - | 220-240 | 140-155 | 300 |

| Working temperature dry (°C) | - | - | -75 to +150 | -30 to +90 | up to 250 |

| Stability to light | poor | poor | poor | poor | good |

| Atmospheric influence | - | - | none | none | none |

| Abrasion resistance | good | good | limited | limited | good |

| Acid resistance | limited-poor | limited-poor | good | good | good |

| Alkaline resistance | good | good | limited | good | good |

| Stability to solvents | limited | limited | good | good | good |

| Hydrolysis resistance | good | good | limited | good | good |

How to select the right filter mesh? You can follow these points.

- Mesh size or the size of the particle you need to filter

- Mesh material (consider the working condition)

- Mesh thread diameter, Mesh thickness

- Opening area

Factory Capabilities

Share Filter can offer the filter mesh in different materials including nylon mesh, polyester mesh, pp mesh,

metallic mesh, and we can convert the filter mesh to filter mesh ribbons, filter mesh tubes, filter mesh

bags and mesh insert plastic molded filters to meet customs' Filtration demands.

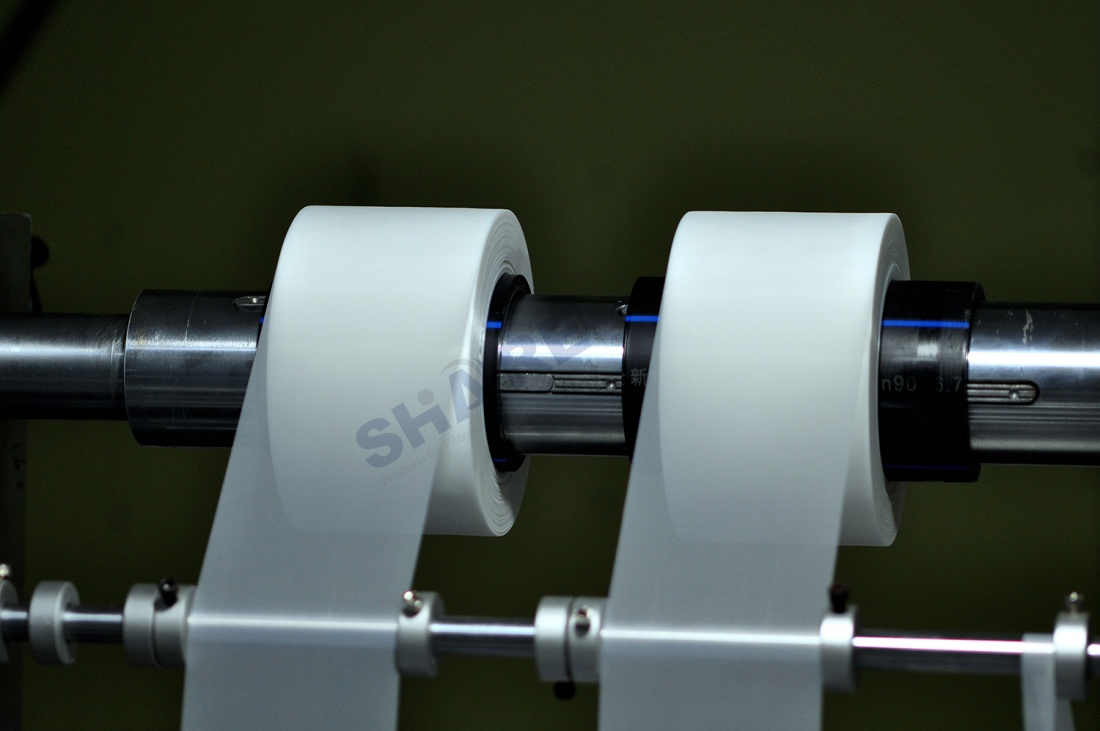

Filter Mesh in Rolls

The width of filter mesh rolls can be in 100cm, 127cm, 150cm,

165cm, 175cm, 183cm, 365cm or

other custom width.

Length can be 30m, 50m, 70m, or other custom length.

Filter Mesh in Narrow Strips

Share Filters ultrasonic slitting is also used for manufacturing

fabric strips and produces a closed edge with

very little material build up at the edge.

Filter Mesh in Cut Shapes.

Our cutting method include Laser cutting, Cold cutting, Hot

cutting, Slitting, Punching. Professional cutting

using custom made tools that will not damage the materials. Custom

size.

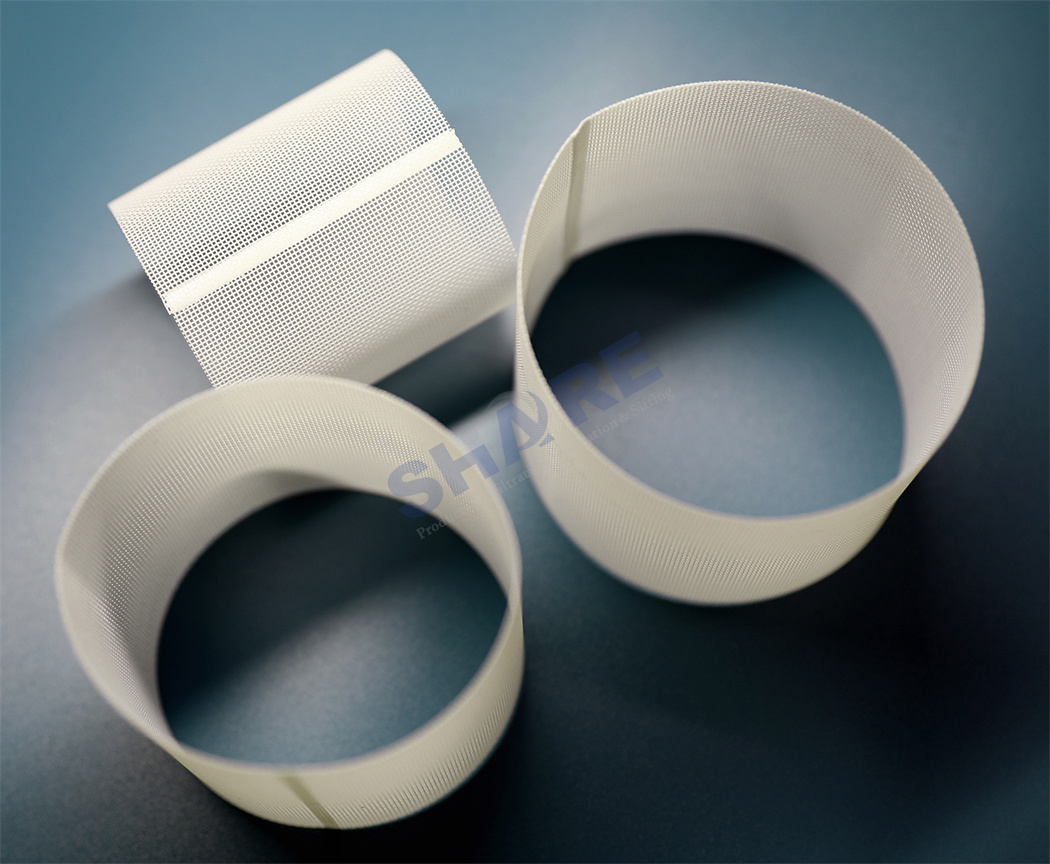

Filter Mesh In Tubes

Sonic welding are accurate, clean. Lapping welding strength to some

degree.

Custom Filter Mesh Bags

For liquid food processing filtration operations, Share Filters has

standard filter bags with galvanized steel

or plastic rings, which are sewn or welded, made of regenerable monofilament filter

cloth from 3 micron to

2000 microns or felt from 0.5 microns to 200 microns. Custom bag is also accepted.

Mesh Insert Plastic Injection Molded Filters

Our injection moulded filters products consist of a synthetic

filter mesh held in a polymer plastic frame,

allowing for a more robust part/product giving more reliability and

longevity in its use.

About Us

Share Filters has over 20 years of experience developing and

manufacturing filter mesh and custom product solutions

for our customer's screen and filtration needs. We can offer the

filter mesh and filter components services including

slitting, cutting, welding, sewing and injection molding. Our

customer base comes from a wide variety of industries

– Automotive, Home appliances, Food and beverage, Milling, Medical,

Life Science and laboratory, Electronical

as well as more general engineering, giving us a wealth of

experience in many areas.

Manufacture Process of Filter Mesh

Share Filters Products Application

|  |  |  |  |

| Automotive | Healthcare | Appliance | Food & Beverage | Environment |