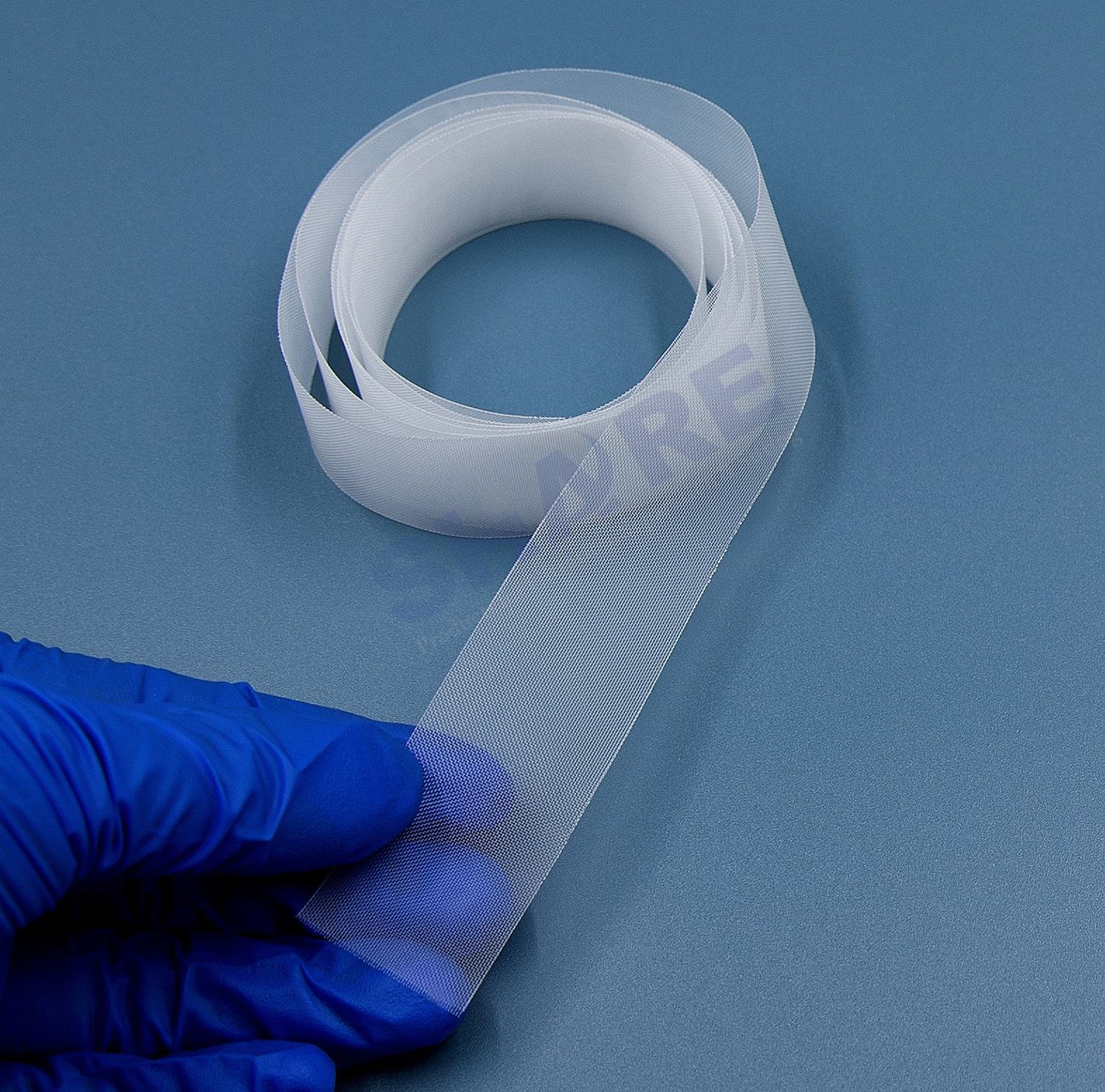

SHARE provides precision filter mesh fabrics for liquid filtration,

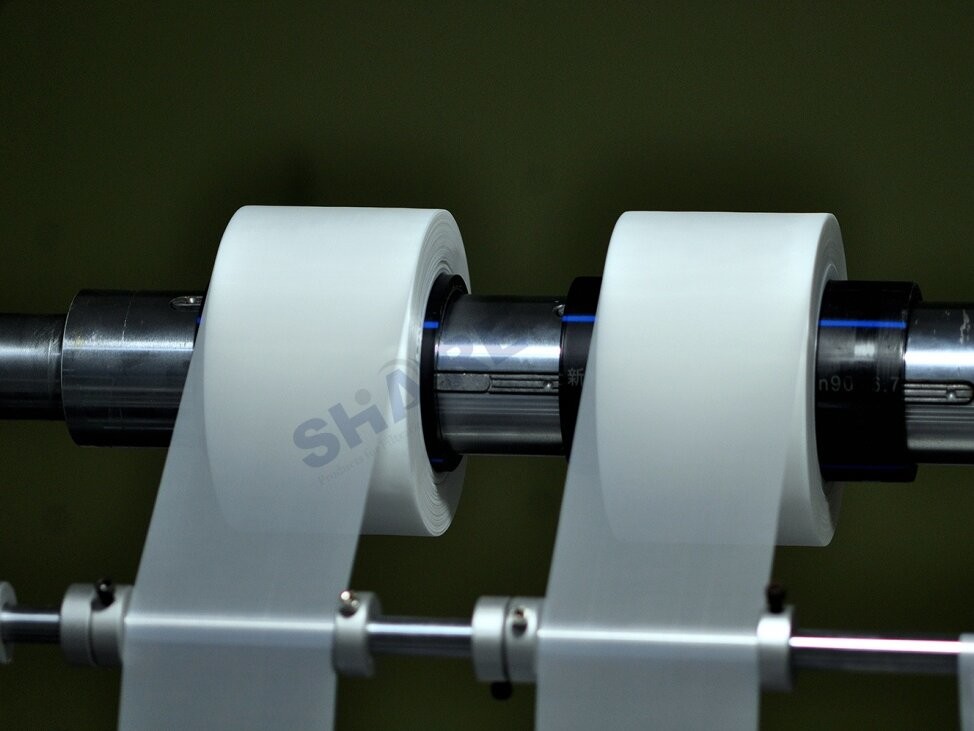

separation and sifting. With special-made processing machines and

equipment, SHARE is capable of heat-sealing, heat-slitting and

cold-stamping mesh into different shapes with ultra-clean edge

quality, width can be down to 1cm.

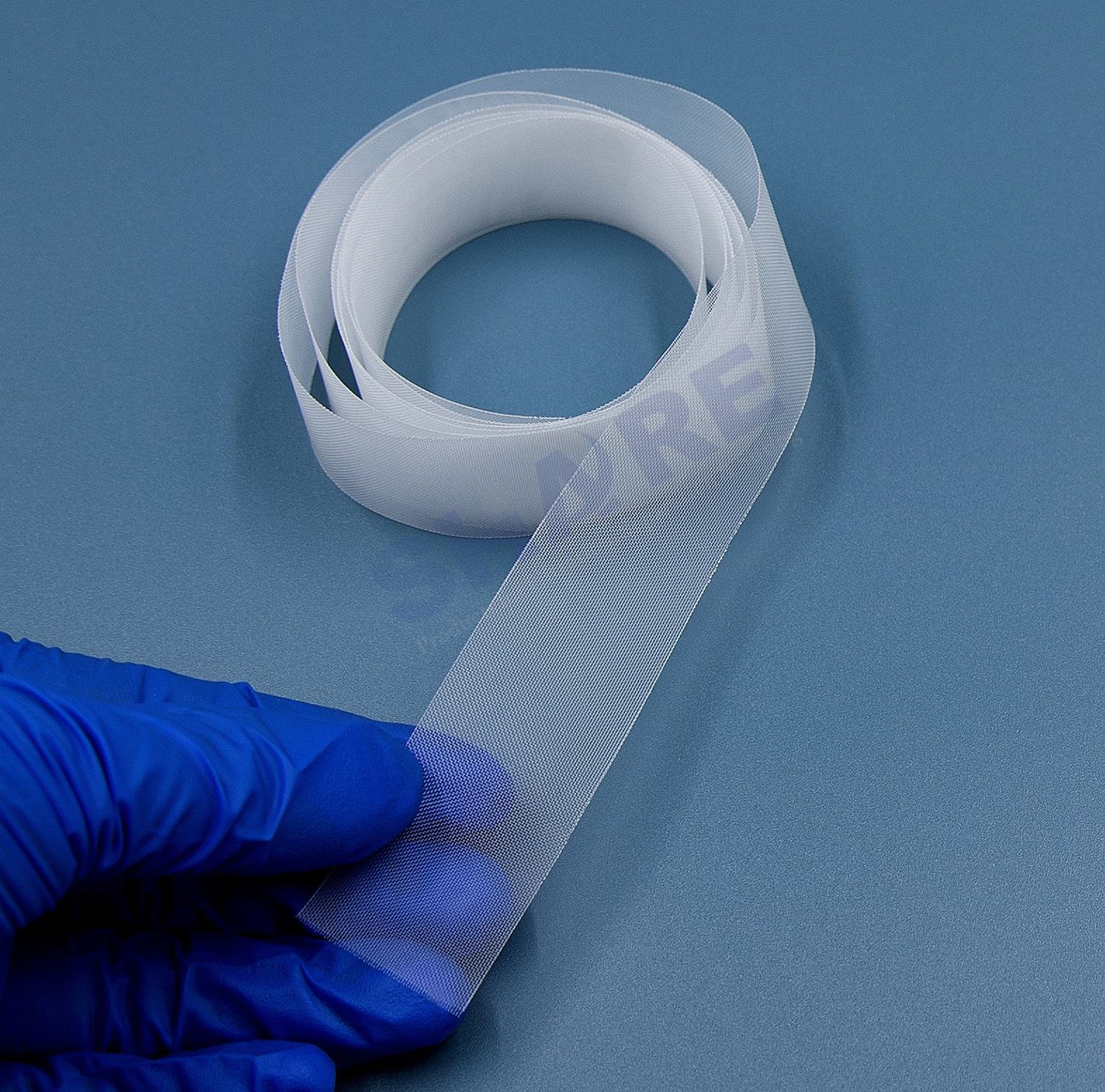

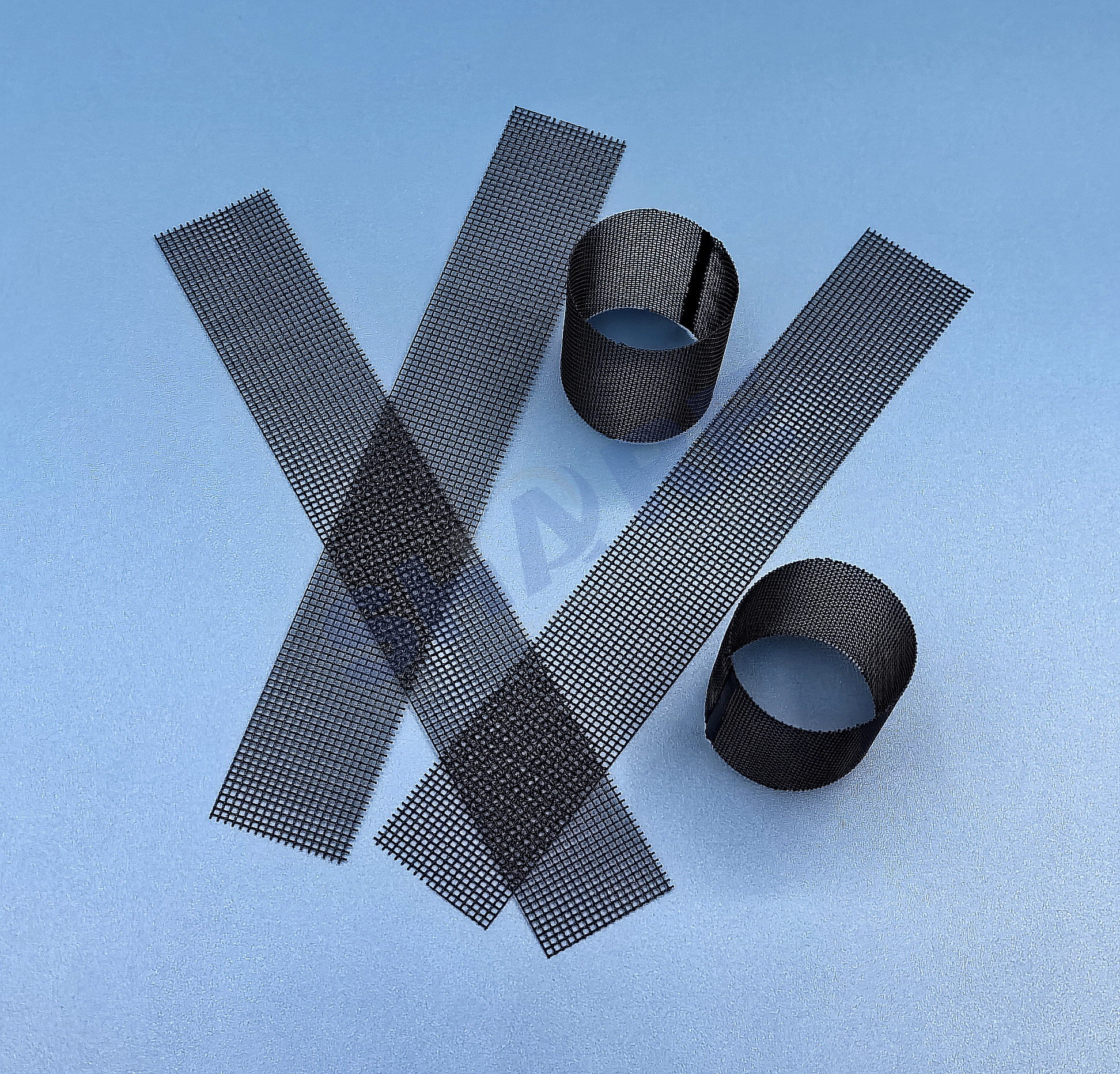

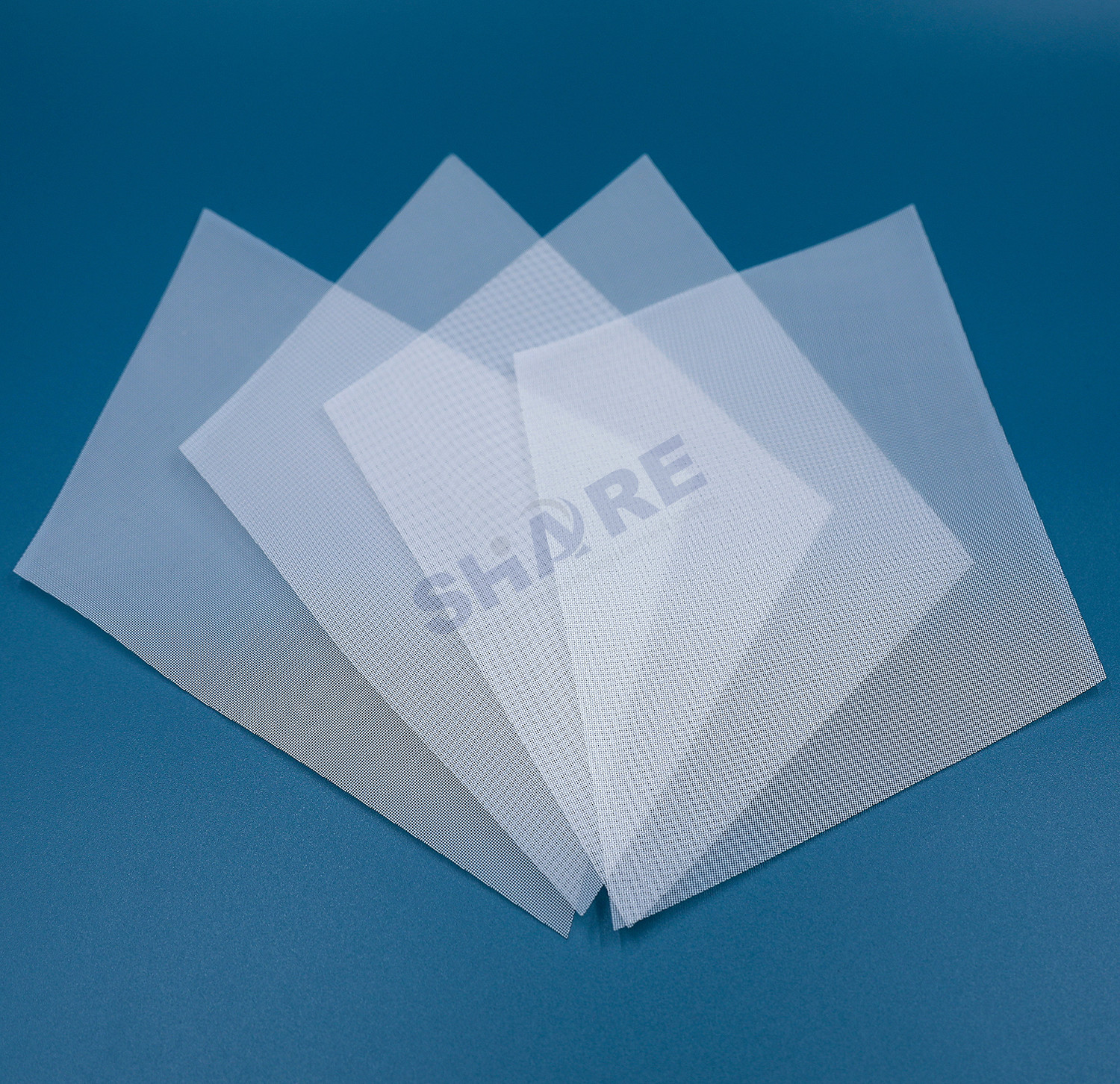

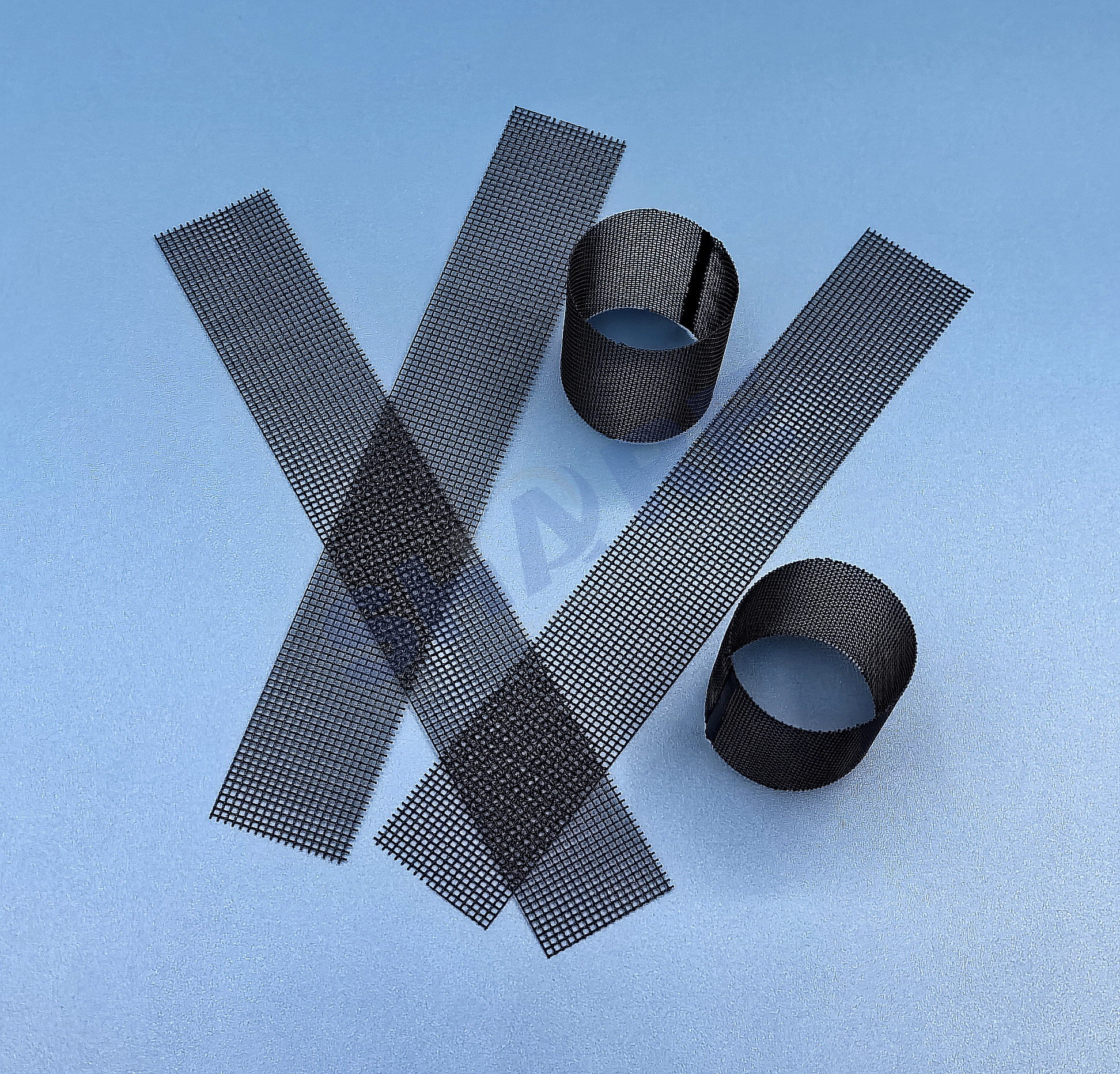

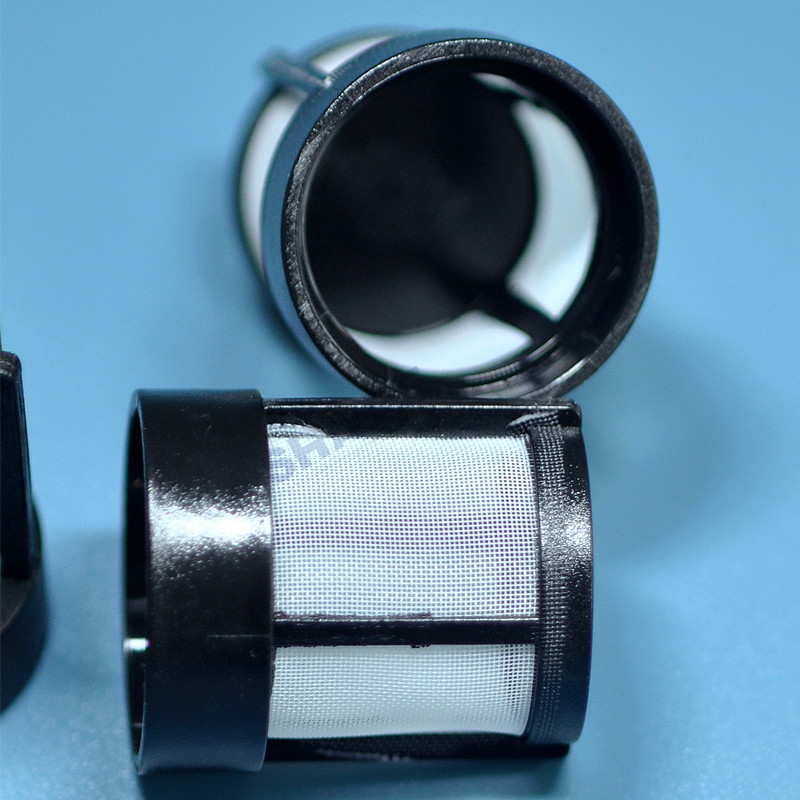

We are able to convert filter mesh fabrics into various specific

sizes and shapes such as discs, stampings, tubes, ribbons, shapes,

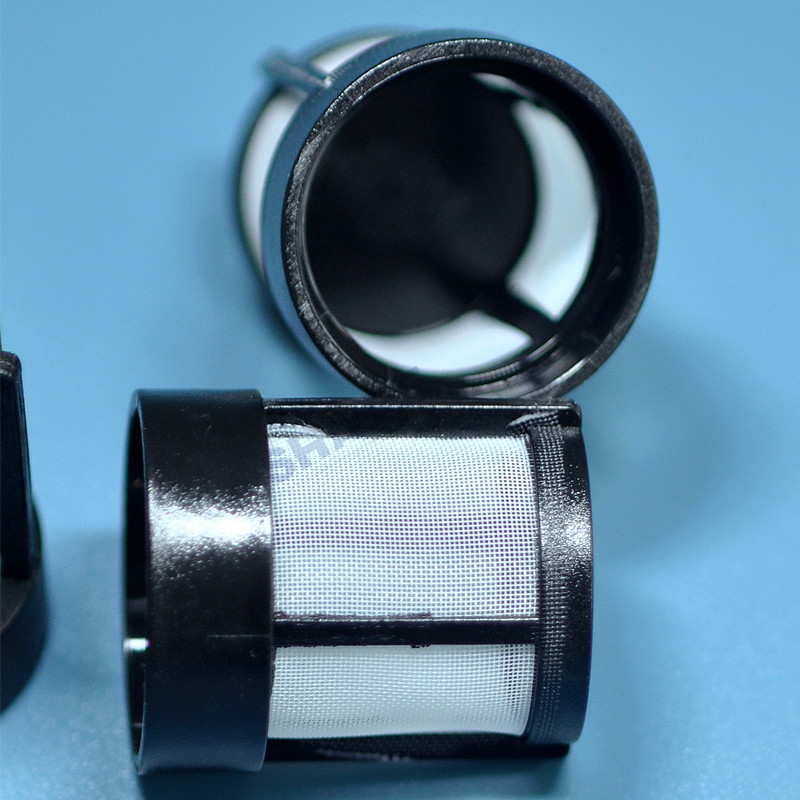

cut-to-size sections, pleated elements, bags, plastic molded filter

and many more. We customize mesh components to fit our customers' needs and

enhance our fabrics with special treatments to improve their

performance.

Processing Technologies

| Processing Technologies | Ultrasonic slitting & welding | Heat cutting & slitting | Laser cutting & slitting | Cold cutting & stamping & punching |

Sewing

|

| Fabrication Method | Mesh materials are slitted while crushing the edge with ultrasonic

vibration | Mesh materials are slitted by heat treatment (temperature close to

melting point) | Almost all shapes and sizes can be processed with laser beam

| Mesh are cut by cold slitting or punching | Various shapes and sizes can be sewn to meet customer demands

|

| Edge Quality | Very clean cut edges |

Closed edge due to melting

| Heat-sealed, non-fraying edges | Non-sealed edge | Sewed edge |

| Advantage | Small material build-up

Narrow tolerances possible

| Possible for most mesh fabrics

|

High flexibility

| The most economical process, possible for all fabrics.

| Very suitable for filter bags, the thread, patch and stitch can be

customized on demand. |

Specifications

| Item name | Heat Seal / Heat Cut Polyester Mesh Filters, Non Fraying Clean Edge |

| Manufacturer | Taizhou Share Filters Co. Ltd. |

| Brand | SHARE FILTERS |

| Samples availability | Free samples are on demand |

| Material | Polyester filter mesh |

| Color | White or other colors |

| Fabrication shape | Round, square, rectangular, trapezoidal, circular, etc. It can be

customized according to your request or drawings |

| Mesh size range | 3-2500 microns for your option. Our application experts will

provide professional advices on mesh size if you are unsure about

it. |

| Product process | Cold, heat, ultrasonic, laser, sew, injection mold |

| Features | 1. Great dimensional stability, accurate and even mesh opening,

smooth surface, excellent tear resistance, high tensile strength,

good air permeability, high chemical resistance, good acid and

solvent resistance, temperature resistance, low moisture absorbency

2. Available in various shapes: disc, ribbon, belt, tube, bag, and

special shapes

3. Compliance with food grade standards

4. RoHS and REACH certified |

| Benefits | Almost unlimited range of shapes (various technologies)

Suited for healthcare applications (FDA compliant, sterile treatment)

Traceability (label)

Non-fraying edges (depending on selected technology)

Accurate width according to request(down to 1cm) |

| Certificate | ISO19001 SGS ROHS REACH |

| Application | Liquid filtration, medical filtration, and semi finished fabricated mesh filters are particularly suitable for use in injection molding processes |

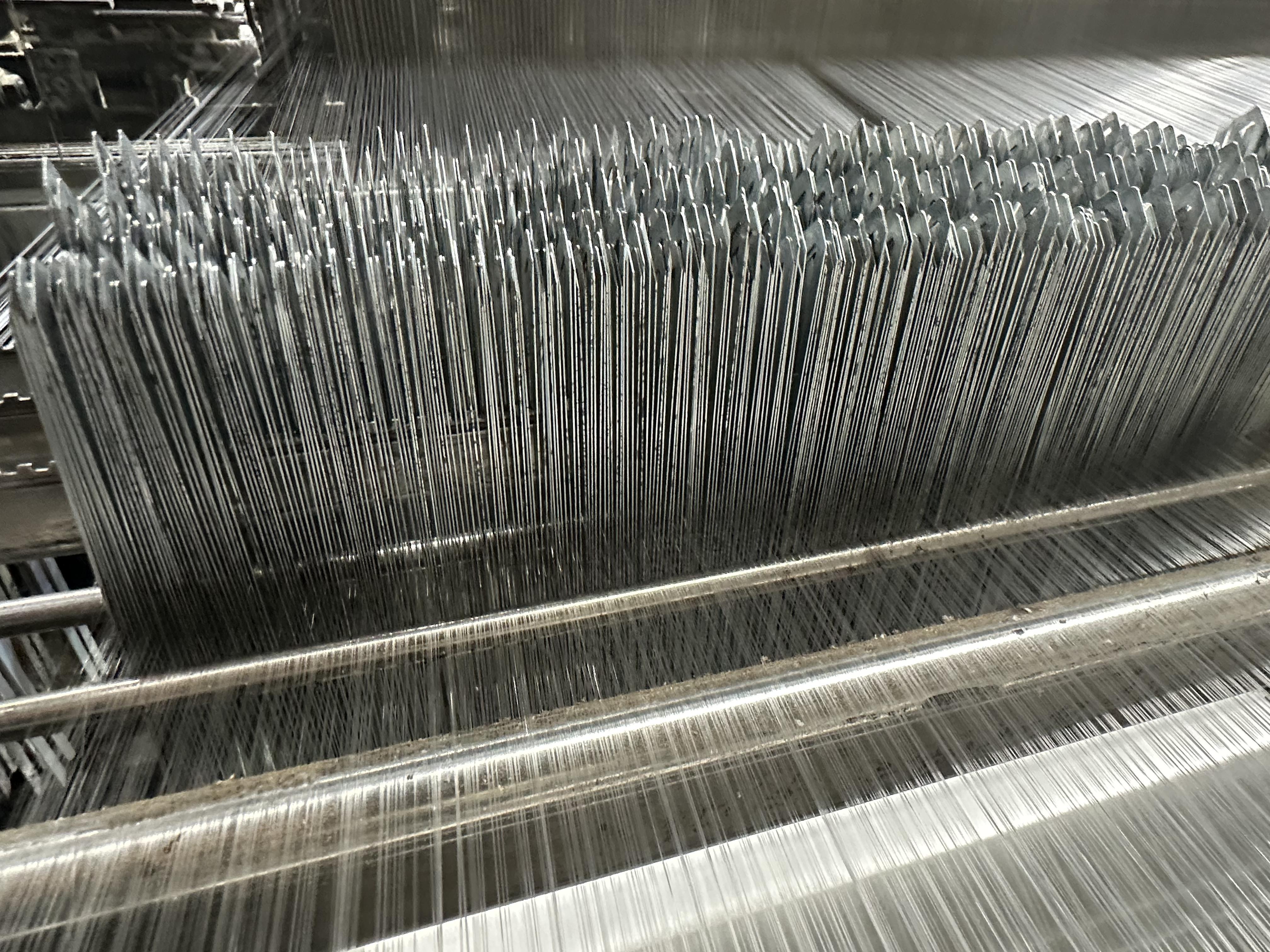

Images

Technical Datasheet

The data sheet of meshes listed below are Polyester. Nylon meshes

or polypropylene meshes are available upon request.

| Precision Polyester Filter Mesh Technical Data Sheet |

Fabric

number | Mesh count | Thread

diameter | Mesh

opening | Open

surface | Fabric

thickness | Weight |

|

| NO. | mesh/cm | mesh/inch | micron | micron | % | micron | g/m2 |

| PES 4400/77.5 | 2T | 5 | 600 | 4400 | 77.5 | 1170 | 156 |

| PES 2750/67.2 | 3T | 8 | 600 | 2750 | 67.2 | 1160 | 234 |

| PES 2000/64 | 4T | 10 | 500 | 2000 | 64 | 950 | 217 |

| PES 1550/60 | 5T | 13 | 450 | 1550 | 60 | 850 | 259 |

| PES 1270/58 | 6T | 15 | 400 | 1270 | 58 | 760 | 246 |

| PES 1080/57 | 7T | 18 | 350 | 1080 | 57 | 660 | 220 |

| PES 900/52 | 8T | 20 | 350 | 900 | 52 | 660 | 251 |

| PES 760/47 | 9T | 23 | 350 | 760 | 47 | 670 | 282 |

| PES 800/64 | 10S | 25 | 200 | 800 | 64 | 360 | 87 |

| PES 750/56 | 10 | 25 | 250 | 750 | 56 | 450 | 160 |

| PES 700/49 | 10T | 25 | 300 | 700 | 49 | 570 | 231 |

| PES 720/74 | 12S | 30 | 120 | 720 | 74 | 215 | 44 |

| PES 680/67 | 12 | 30 | 150 | 680 | 67 | 260 | 69 |

| PES 580/48 | 12 | 30 | 250 | 580 | 48 | 460 | 192 |

| PES 530/40 | 12T | 30 | 300 | 530 | 40 | 580 | 277 |

| PES 515/52 | 14S | 36 | 200 | 515 | 52 | 360 | 143 |

| PES 470/50 | 15S | 38 | 200 | 470 | 50 | 380 | 154 |

| PES 420/40 | 15T | 38 | 250 | 420 | 40 | 470 | 240 |

| PES 525/92 | 16S | 41 | 100 | 525 | 92 | 180 | 36 |

| PES 425/46 | 16T | 41 | 200 | 425 | 46 | 380 | 164 |

| PES 405/53 | 18S | 46 | 150 | 405 | 53 | 260 | 104 |

| PES 375/46 | 18T | 46 | 180 | 375 | 46 | 330 | 150 |

| PES 375/51 | 19T | 48 | 150 | 375 | 51 | 260 | 110 |

| PES 420/71 | 20S | 50 | 80 | 420 | 71 | 140 | 33 |

| PES 400/64 | 20S | 50 | 110 | 400 | 64 | 180 | 51 |

| PES 350/49 | 20T | 50 | 150 | 350 | 49 | 260 | 115 |

| PES 325/47 | 21T | 53 | 150 | 325 | 47 | 270 | 121 |

| PES 340/67 | 24S | 61 | 120 | 340 | 67 | 220 | 88 |

| PES 270/42 | 24T | 61 | 150 | 270 | 42 | 280 | 138 |

| PES 250/46 | 27T | 68 | 120 | 250 | 46 | 230 | 100 |

| PES 280/62 | 28S | 71 | 80 | 280 | 62 | 150 | 46 |

| PES 240/45 | 28T | 71 | 120 | 240 | 45 | 230 | 103 |

| PES 225/43 | 29T | 74 | 120 | 225 | 43 | 230 | 107 |

| PES 215/42 | 30T | 76 | 120 | 215 | 42 | 230 | 111 |

| PES 230/54 | 32S | 80 | 80 | 230 | 54 | 150 | 52 |

| PES 210/45 | 32T | 80 | 100 | 210 | 45 | 180 | 82 |

| PES 215/53 | 34S | 86 | 80 | 215 | 53 | 150 | 56 |

| PES 195/44 | 34T | 86 | 100 | 195 | 44 | 180 | 87 |

| PES 180/42 | 36T | 91 | 100 | 180 | 42 | 180 | 92 |

| PES 200/61 | 39S | 99 | 55 | 200 | 61 | 95 | 30 |

| PES 190/55 | 39T | 99 | 64 | 190 | 55 | 115 | 40 |

| PES 150/36 | 40T | 102 | 100 | 150 | 36 | 190 | 103 |

| PES 150/42 | 43T | 110 | 80 | 150 | 42 | 155 | 71 |

| PES 160/57 | 47S | 120 | 55 | 160 | 57 | 96 | 36 |

| PES 150/50 | 47T | 120 | 64 | 150 | 50 | 120 | 48 |

| PES 140/43 | 47HD | 120 | 71 | 140 | 43 | 130 | 59 |

| PES 140/47 | 49S | 125 | 64 | 140 | 47 | 120 | 50 |

| PES 135/44 | 49T | 125 | 71 | 135 | 44 | 130 | 62 |

| PES 144/55 | 53S | 135 | 45 | 144 | 55 | 76 | 27 |

| PES 135/51 | 53S | 135 | 55 | 135 | 51 | 97 | 40 |

| PES 125/44 | 53T | 135 | 64 | 125 | 44 | 122 | 54 |

| PES 117/39 | 53T | 135 | 71 | 117 | 39 | 132 | 67 |

| PES 115/46 | 59S | 150 | 55 | 115 | 46 | 99 | 45 |

| PES 105/38 | 59T | 150 | 64 | 105 | 38 | 123 | 61 |

| PES 100/41 | 64S | 160 | 55 | 100 | 41 | 100 | 48 |

| PES 90/33 | 64T | 160 | 64 | 90 | 33 | 125 | 66 |

| PES 95/47 | 72S | 180 | 45 | 95 | 47 | 78 | 37 |

| PES 85/38 | 72T | 180 | 55 | 85 | 38 | 102 | 55 |

| PES 75/33 | 77T | 195 | 55 | 75 | 33 | 105 | 58 |

| PES 80/41 | 80S | 200 | 45 | 80 | 41 | 80 | 41 |

| PES 85/44 | 80T | 200 | 48 | 85 | 44 | 86 | 44 |

| PES 70/40 | 90M | 230 | 39 | 70 | 40 | 68 | 34 |

| PES 68/34 | 90T | 230 | 45 | 68 | 34 | 80 | 46 |

| PES 65/33 | 90T | 230 | 48 | 65 | 33 | 82 | 49 |

| PES 60/36 | 100T | 250 | 39 | 60 | 36 | 69 | 38 |

| PES 56/38 | 110T | 280 | 34 | 56 | 38 | 62 | 34 |

| PES 52/33 | 110HD | 280 | 39 | 52 | 33 | 70 | 42 |

| PES 52/40 | 120S | 300 | 31 | 52 | 40 | 48 | 32 |

| PES 48/33 | 120T | 300 | 34 | 48 | 33 | 63 | 37 |

| PES 44/28 | 120HD | 300 | 39 | 44 | 28 | 72 | 46 |

| PES 47/37 | 130S | 330 | 31 | 47 | 37 | 50 | 35 |

| PES 42/30 | 130T | 330 | 34 | 42 | 30 | 58 | 40 |

| PES 43/34 | 140S | 350 | 31 | 43 | 34 | 50 | 37 |

| PES 36/25 | 140T | 355 | 34 | 36 | 25 | 62 | 43 |

| PES 37/30 | 150S | 380 | 31 | 37 | 30 | 50 | 40 |

| PES 32/24 | 150 | 381 | 34 | 32 | 24 | 56 | 43 |

| PES 33/31 | 165S | 420 | 27 | 33 | 31 | 40 | 26 |

| PES 32/23 | 165T | 420 | 31 | 32 | 23 | 50 | 36 |

| PES 25/16 | 165 | 419 | 34 | 25 | 16 | 66 | 49 |

| PES 24/18 | 180 | 457 | 27 | 24 | 18 | 43 | 33 |

| PES 23/17 | 180 | 457 | 31 | 23 | 17 | 56 | 40 |

| PES 18/18 | 235x245 | 597x622 | 24 | 18 | 18 | 44 | 32 |

| PES 18/13 | 200 | 508 | 31 | 18 | 13 | 60 | 48 |

| PES 23/25 | 200T | 500 | 27 | 23 | 25 | 45 | 32 |

| PES 15/10 | 200x215 | 508x546 | 31 | 15 | 10 | 59 | 50 |

The data are compiled to the best of our knowledge. Subject to

change without notice. Current data are available on you demand.

Mesh Count: Number of openings per inch or centimeter

Weave Type: Plain Weave (PW) or Twill Weave (TW)

Thread Diameter: The diameter of each thread before weaving

Mesh Thickness: The average thickness of the woven mesh

Mesh Opening: The distance between adjacent threads

Open Area: The ratio (%) of the open area to the thread area within a woven

mesh

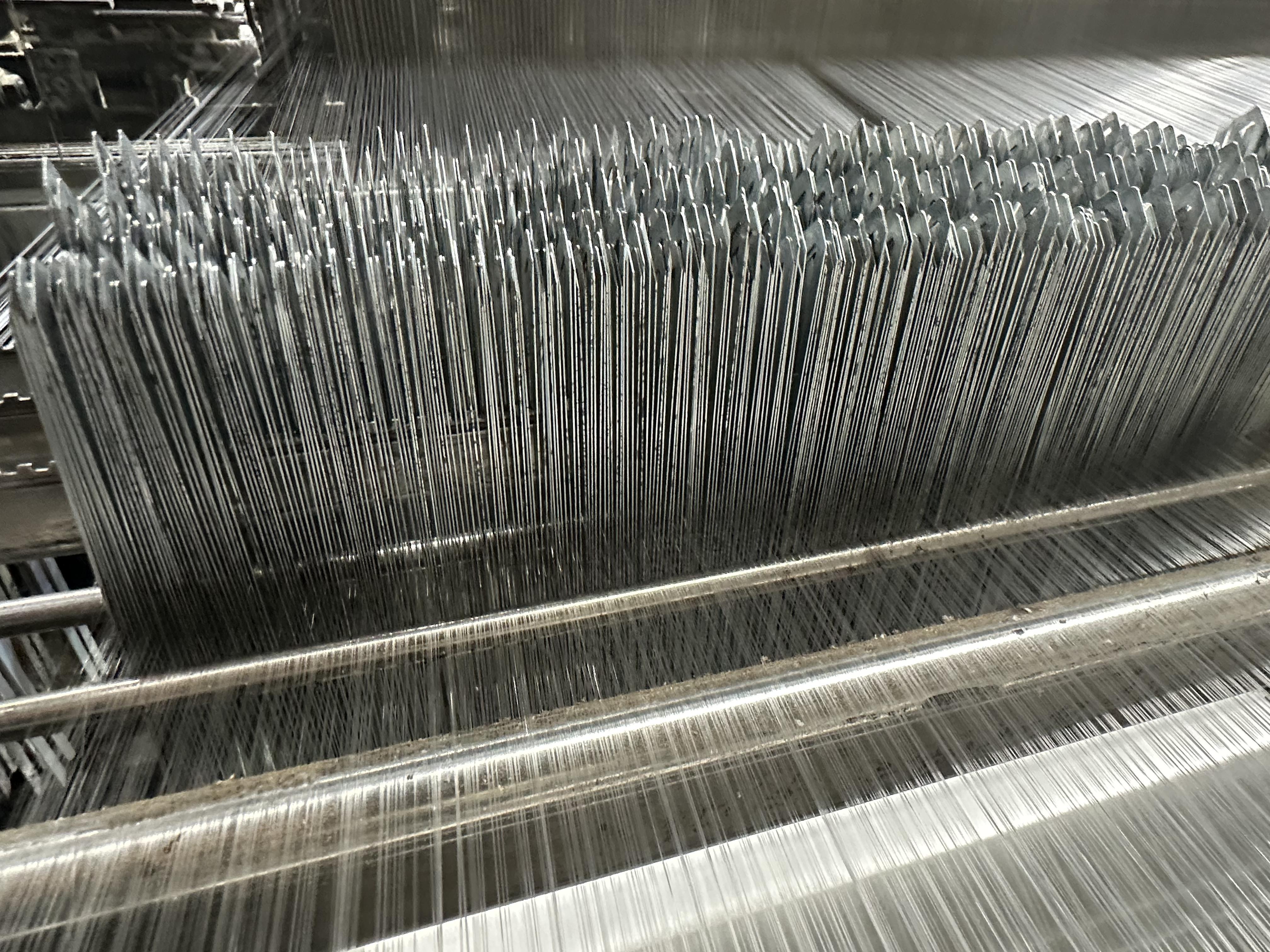

Production Process

Yarn

Monofilament

- Excellent diameter control for precise openings

- High flow rates and low pressure drops

- Filtration by surface particle capture

- Excellent surface particle release, easy to clean

- High degree of stiffness

Weave

Plain Weave

Plain weave is made by crossing the warp and weft yarns with each

other. Well-regulated and highly durable textile fabrics can be

created as there are many points where the threads cross each other

(structure points). It is also resistant to friction.

Since the warp and weft yarns appear on the front and rear surfaces

of the textile uniformly, it is sometimes difficult to make a

distinction between the front side and the rear side compared to

other structures.

Product Procedure

Yarn→Raw yarn inspection→Warping arranging→Drawing in

heddle→Drawing in reed→Weaving→Initial survey→Washing→Heat setting

treatment→Physical properties inspection→Products

inspection→Product→Fabricated mesh if needed→Plastic molded filters

if needed

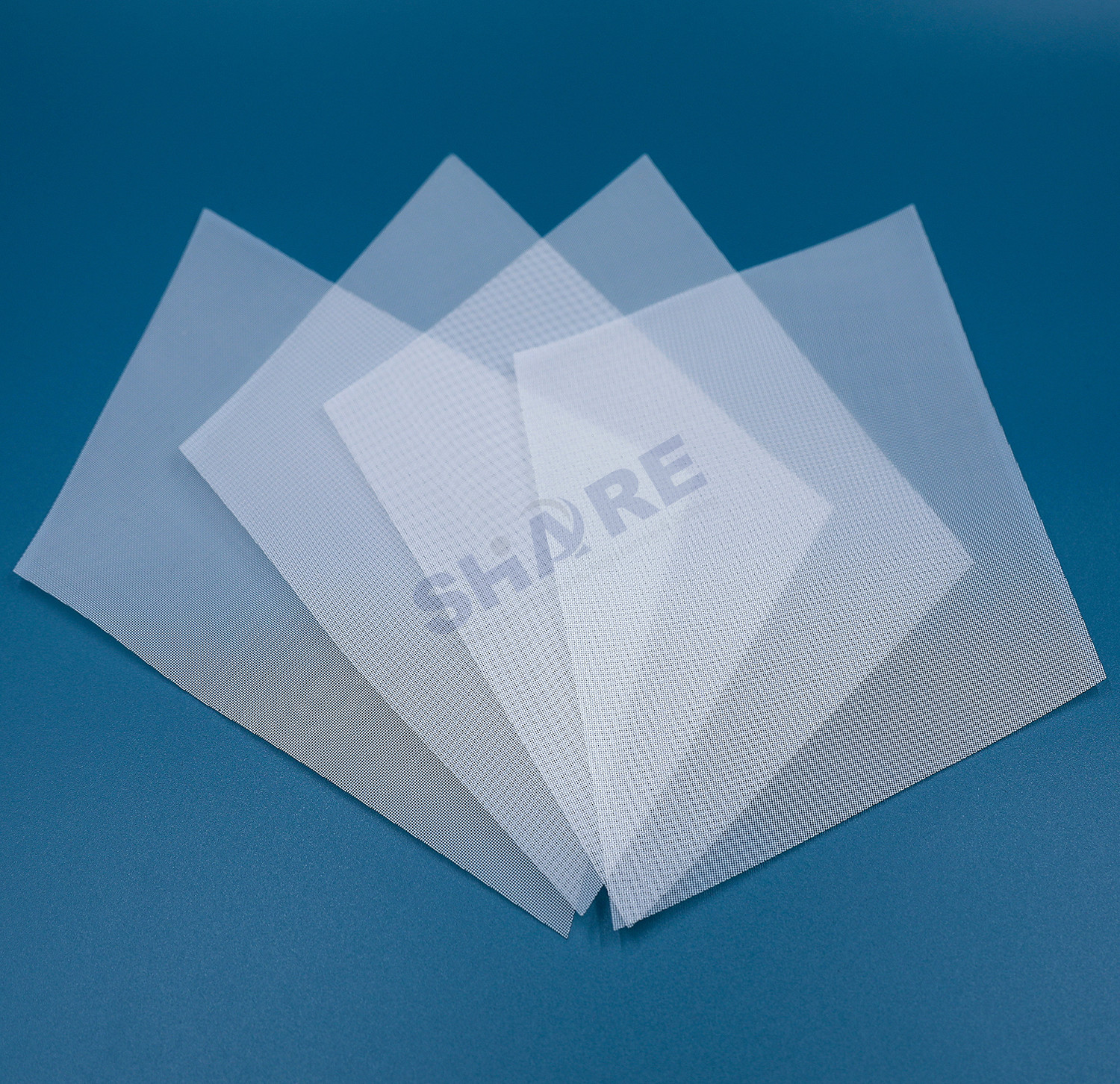

Mesh

SHARE precision filter mesh has smooth surface, great dimensional

stability and strength than other material options, and tighter

tolerance. It has different but precise mesh opening from 3um to

4400um. These allow for the different sized filter meshes to be

used in different situations and for different purposes, such as

home appliance, liquid filtration, dust collection or separation,

dry and wet filter bags, sifting, milling, automotive, medical,

food, pharmaceutical, molded filters and many more.

SHARE can further processed filter mesh into various forms of

custom filters, such as filter pieces, shapes, ribbons, tubes,

plastic filters by our state-of-the-art technologies of cutting, stitching, gluing, welding, laser cutting, molding and

more, to fuifil customers and markets' demanding filtration and

screening needs.

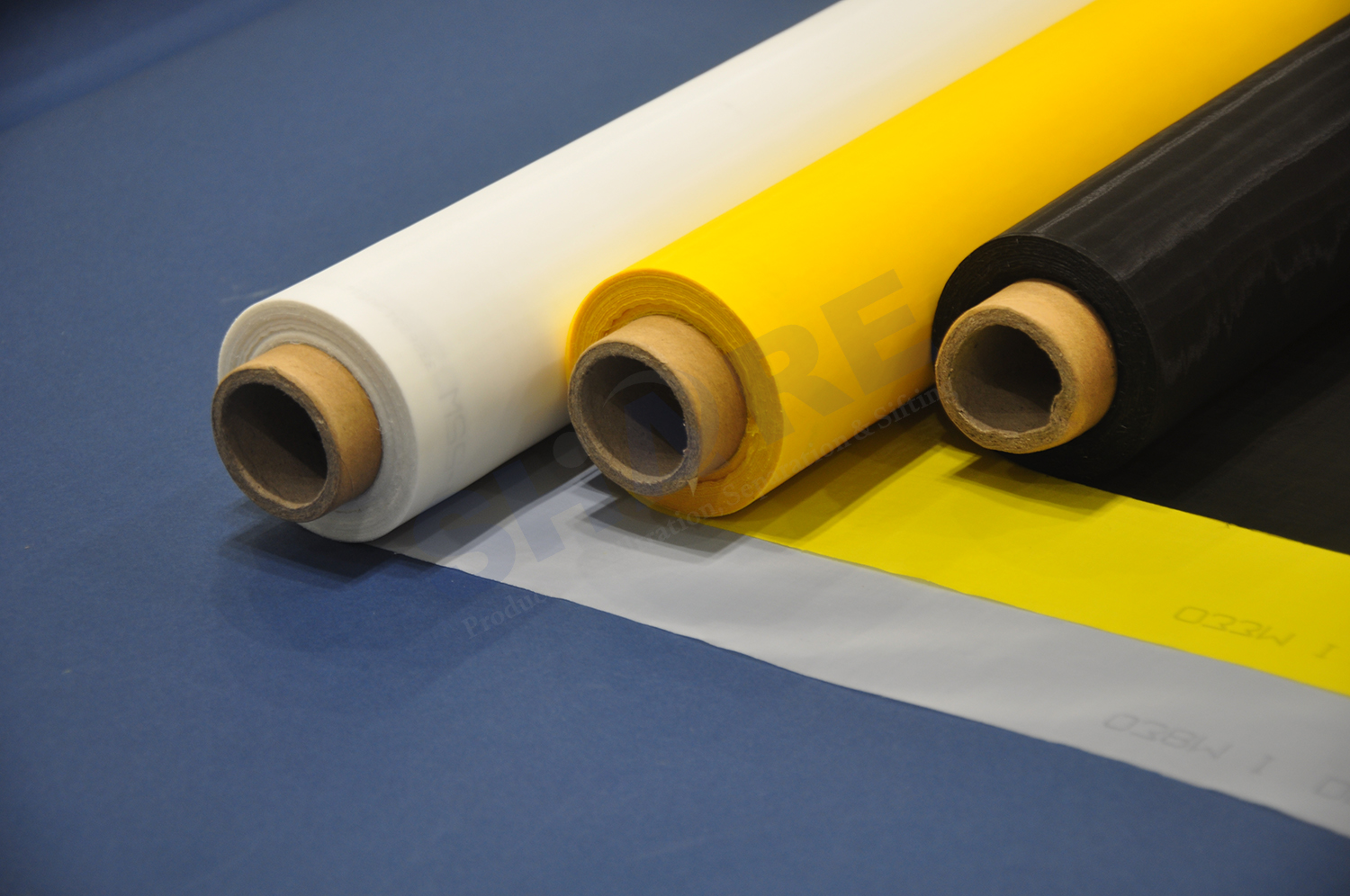

Established in 1983, Taizhou Share Filters Co., Ltd. offers a

comprehensive range of woven monofilament filter mesh

fabrics(nylon, polyester, polypropylene etc.) with micron ratings

ranging from 3um to 4mm. We specialize in engineering woven fabrics

into finished or partly finished products.

Our products are categorized into three classes.

Monofilament Mesh Rolls - 30 years of experience & capabilities

- PA, PET, PP, PE, PPS, PEEK etc.

- Characterized by precise mesh opening, open area and thickness

- Excellent converting capabilities from yarn over weaving to

converted items

| |

Discs, Tubes, Ribbons, Bags - Cutting, calendering, welding, slitting, sewing, pleating, molding

- Discs, tubes, ribbons, bags etc.

- Various converting capabilities by stamping or slitting technology:

cold, heat, laser, ultrasonic

- Clean, smooth & closed edge quality

- Maximum compatibility with injection molding process

| |

Plastic Molded Filters - Insert molding and over molding

- Mold design, modeling, prototyping, manufacturing and testing

- High efficiency, excellent particles holding capacity and low

pressure drop

- High stability, repeatability and reliability

- Extensive material options and industry-best lead times

| |

Whether you want to improve the quality or reduce the cost of your

existing filter component, plan a new filtration application, or

need assistance with specifications and design validation, SHARE

application specialists with decades of experience will help you

create the best filter solution for your application.

Contact SHARE today for additional information and how we can help

you with your specific filtration requirements.

Packaging & Shipping

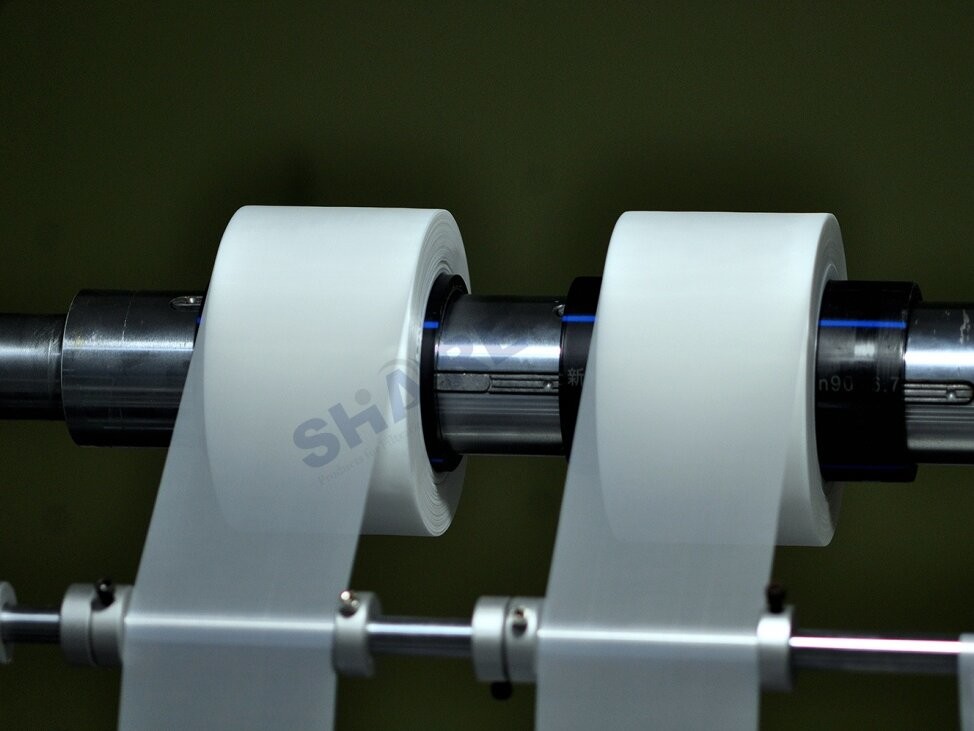

1. Rolled on the paper core, 30-70m/roll, packed into PE bags, the product label is attached on the edge of each roll

2. 2-8 rolls per standard export carton

3. Put into PP woven bag to prevent damage during transportation

4. Package belt strengthen

For fabricated & molded filters:

1. Packed into sealed PE bags, 10m2 to 500m2/bag according to the

actual size, double bagged and the product label is attached in the

inner bag

2. Put into bigger PE bag and then standard export carton

3. Wrapped the outer carton with PE stretch film to prevent damage

during transportation

4. Package belt strengthen if pallets are available

The label contains the following standard information:

item name, manufacturer, material, dimensions, manufacturing date,

order number, batch number etc.

| Port to Port | Door to Door |

| Express(DHL,UPS,FEDEX, EMS) | | 1 - 5 days |

| Air Freight | 1 - 5 days | 4 - 10 days |

| Sea Freight(FCL) | 15 - 30 days | 20 - 35 days |

| Sea Freight(LCL) | 15 - 30 days | 22 - 37 days |

FAQ

1. Where is your factory located? How can I visit there?

We are in Taizhou city, Zhejiang province China. By train, we are

one hour away from Hangzhou and two hours away from Shanghai.

2. Can I get free samples and how long can you deliver them?

We are pleased to provide you with free samples for your evaluation, which will be sent to you within 2 days. Please feel free to reach out to us for samples.

3. How long does a quotation take?

In most cases, we respond within 2 days. If something in RFQ need be confirmed, we will promptly

notify you soon.

4. How quickly can I get my order finished?

The production lead time is dependent on the quantity. Typically,

it takes 5 to 15 working days for us to complete mass production once you have

placed the order.

5. What about your quality control?

By visual inspection, optical or pressure sensitive equipment and

automated 3D image-inspection equipment, our production operators

conduct self-inspections at every stage of the process.

Additionally, we have spot inspections and final inspections

carried out by our Quality Control (QC) team.

6. What's your largest advantage?

One of our core competencies is our excellent converting

capabilities from yarn over weaving to converted items with

professional technical team and quality guarantee and management

for more than 30 years.

7. What kind of payment terms do you accept?

T/T and LC and more.