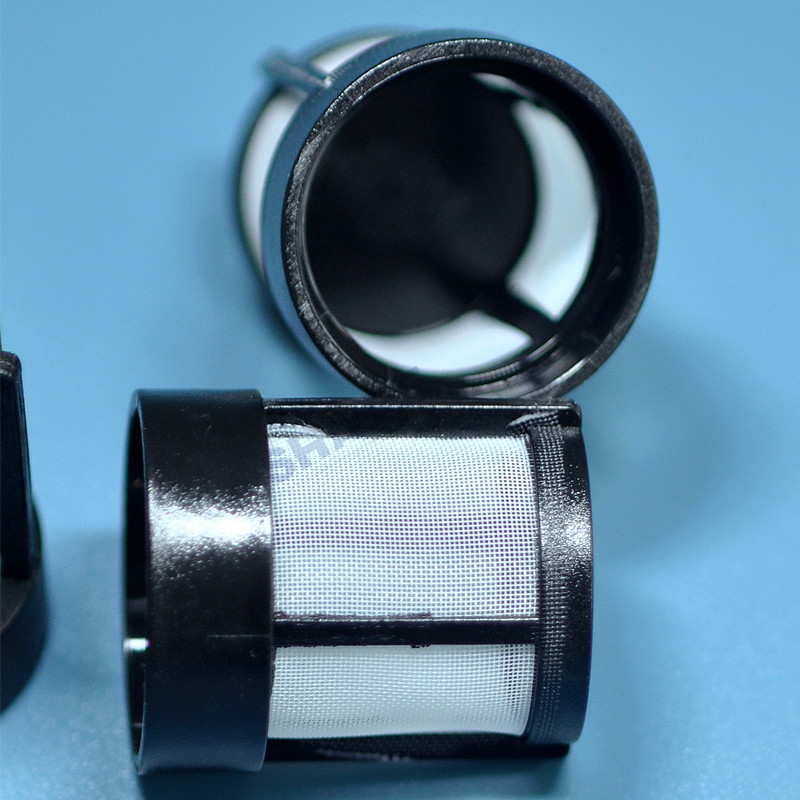

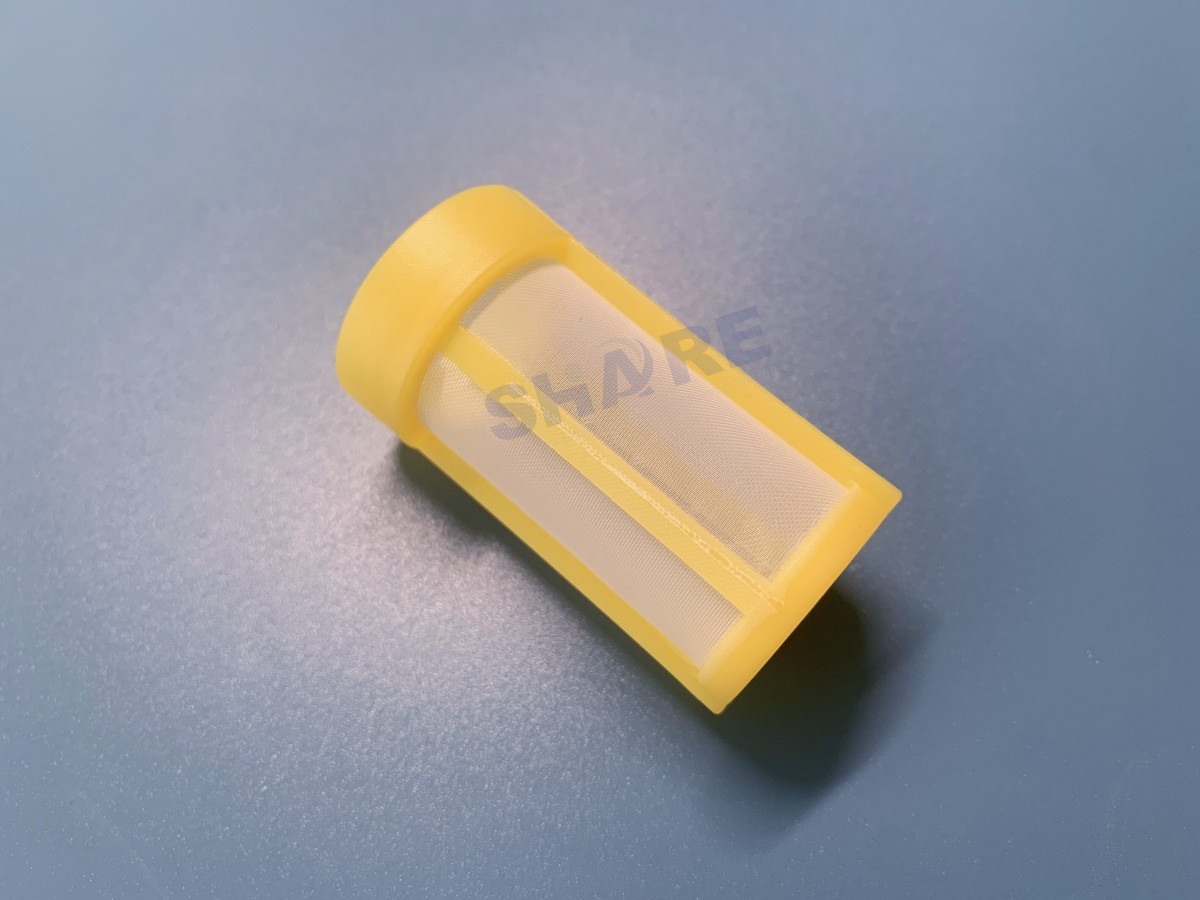

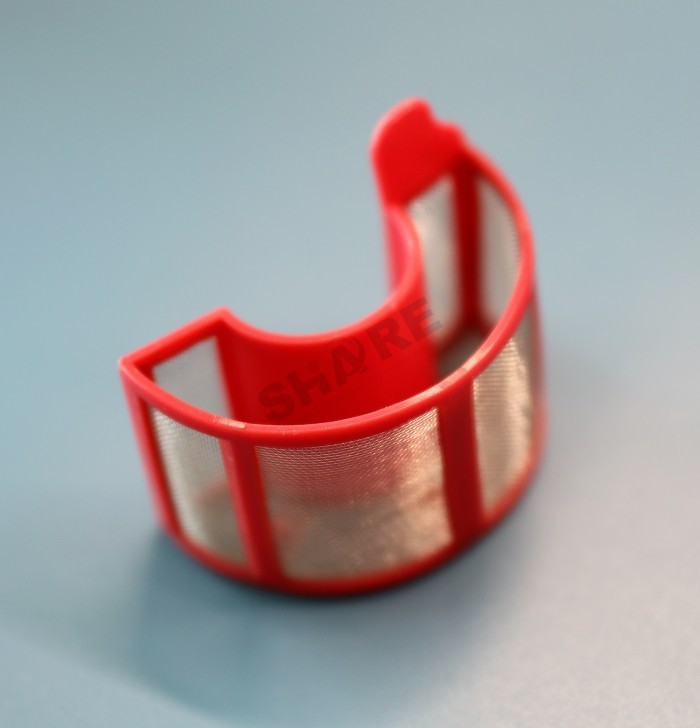

We specialize in designing and developing various filter components

for household appliances, such as dishwasher filters, washing

machine filters, tumble dryer filters, water filtration, spray and

foam nozzles filters, refrigerators filters, freezers filters, air

conditioners filters, water purifiers, vacuum cleaners filters,

hair dryer filters, water and pool filters, air purifiers.

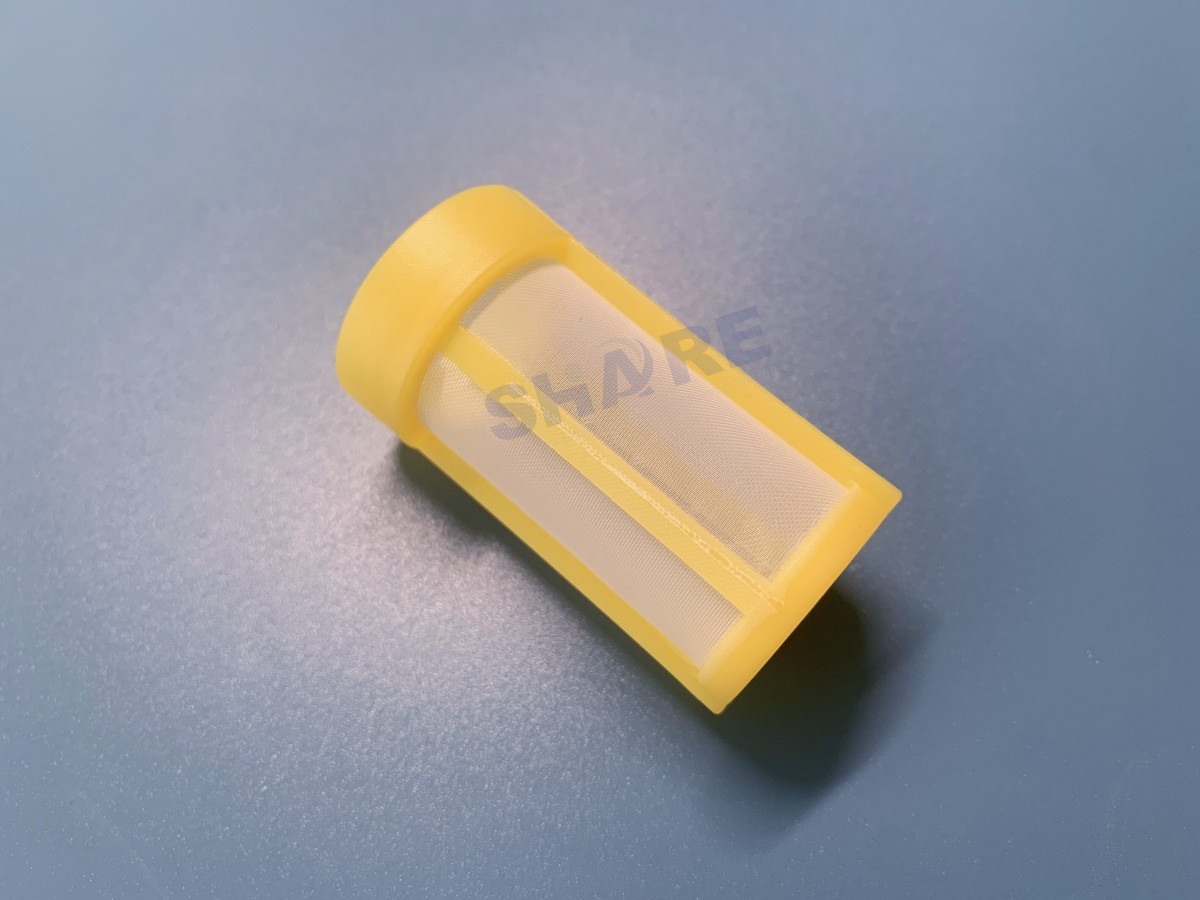

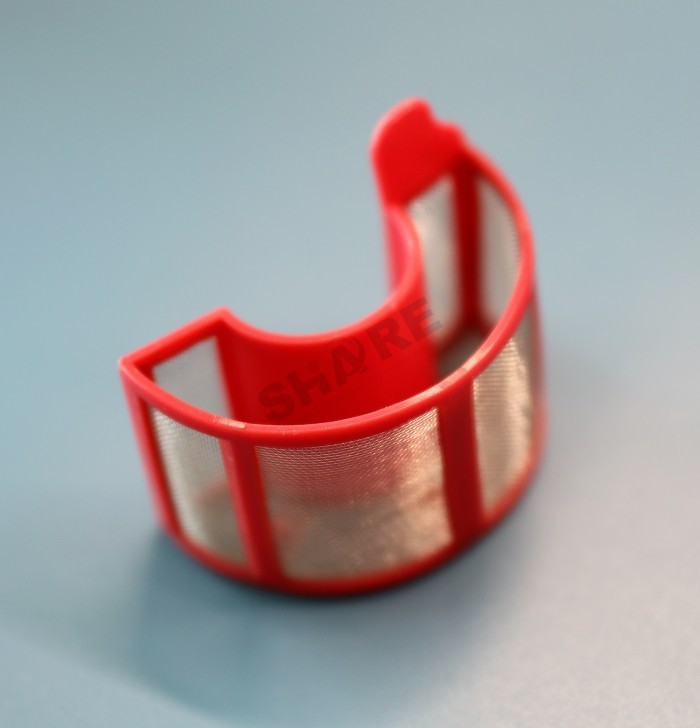

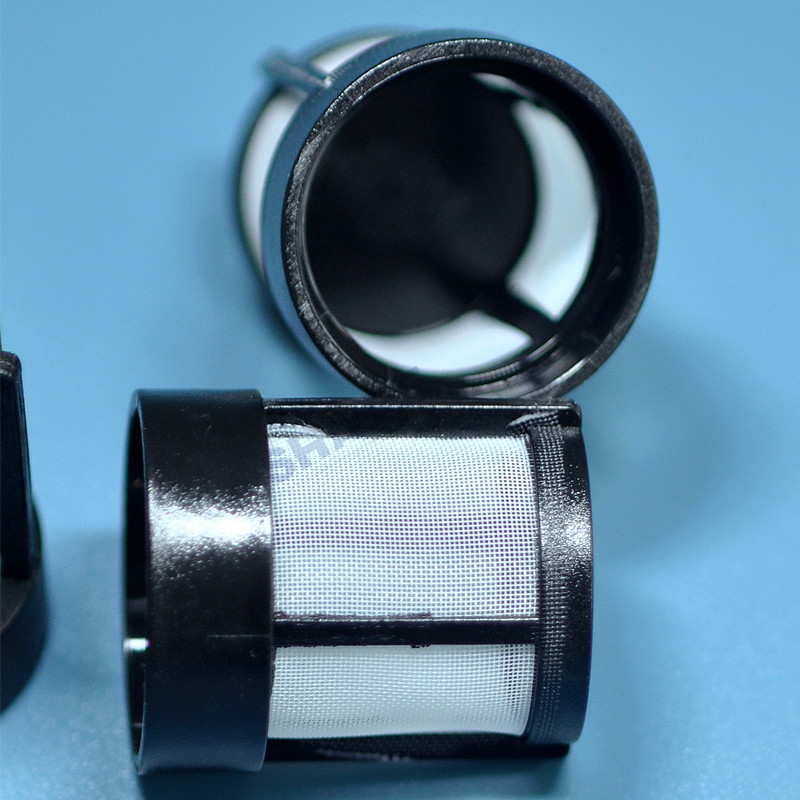

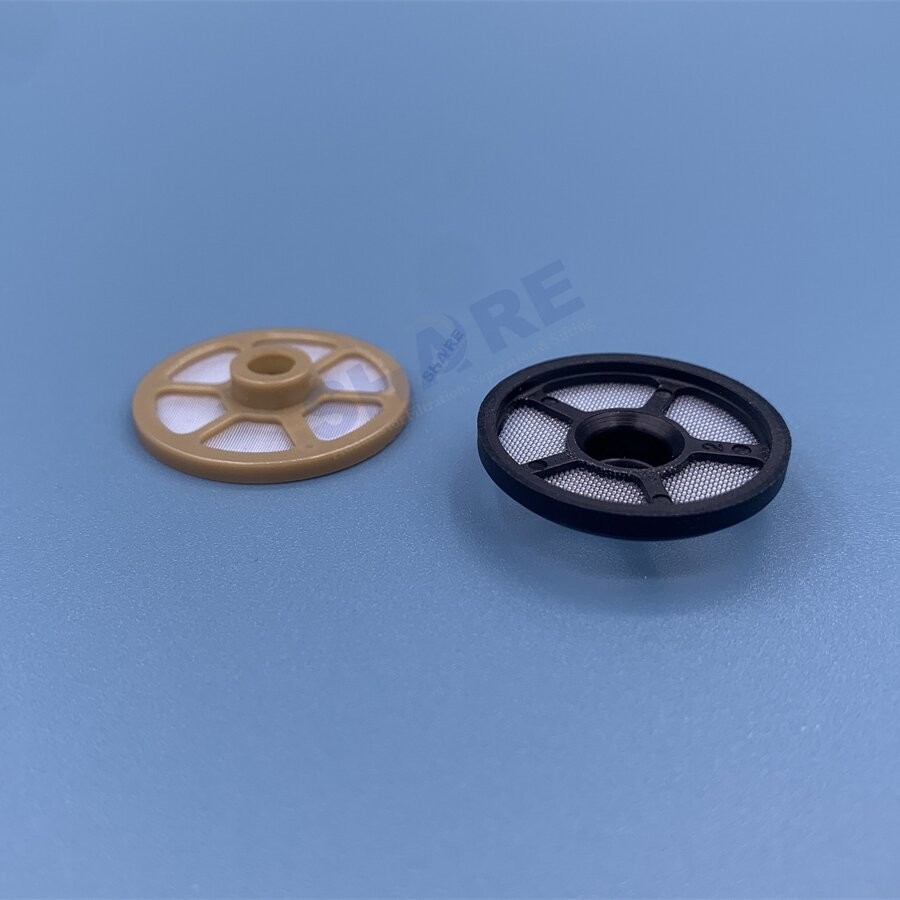

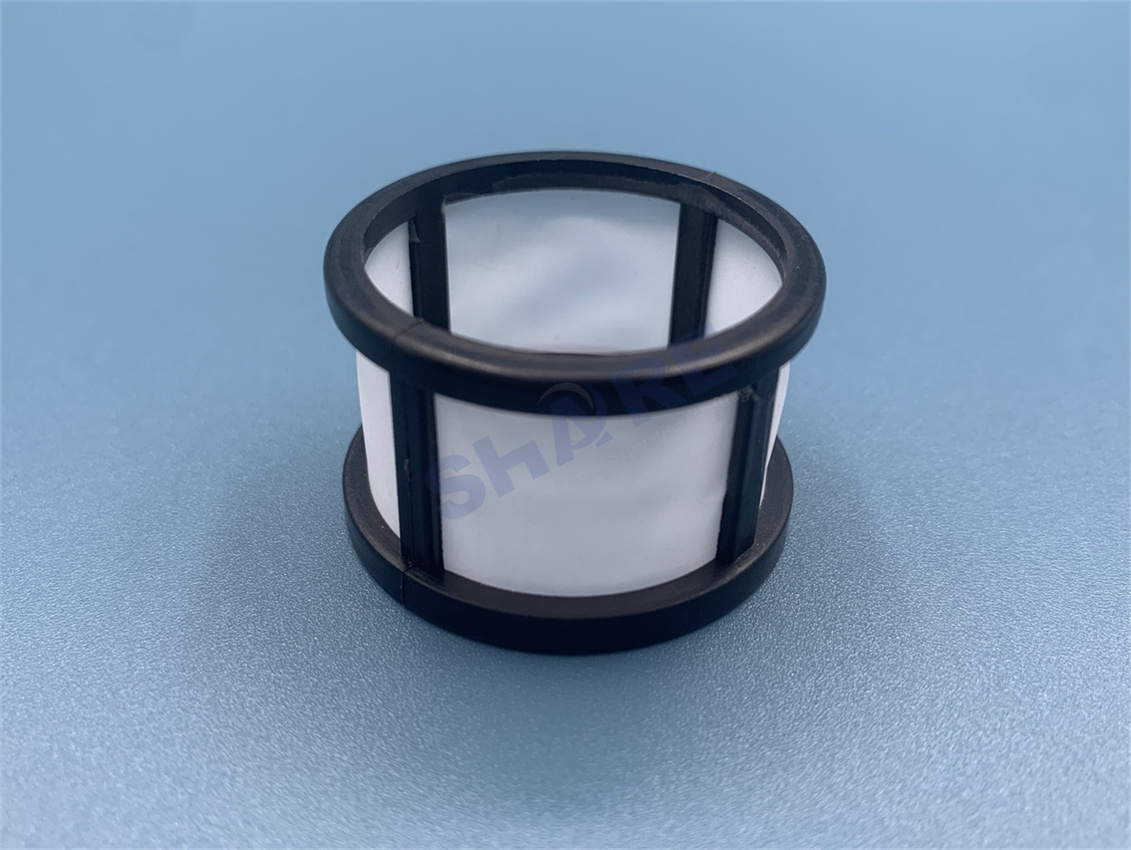

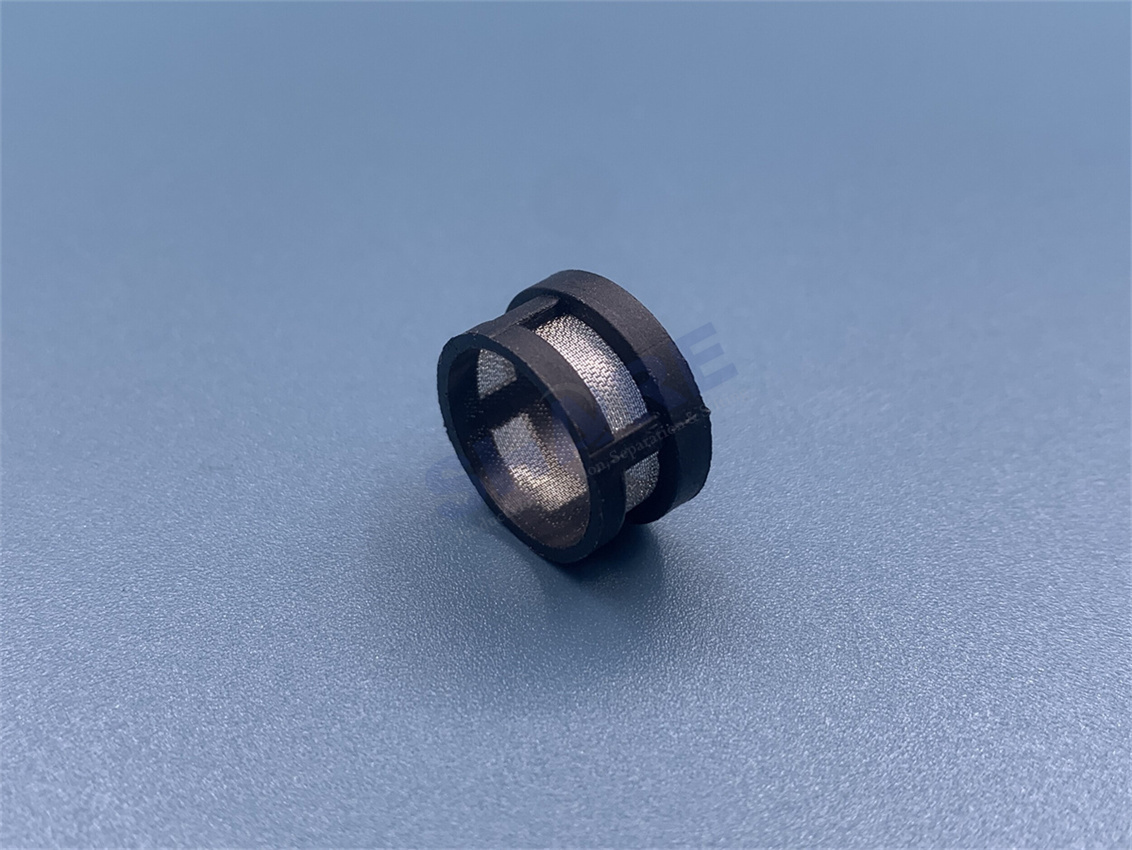

Plastic Molded Polyester Filter Screen Panels for Air Conditioner

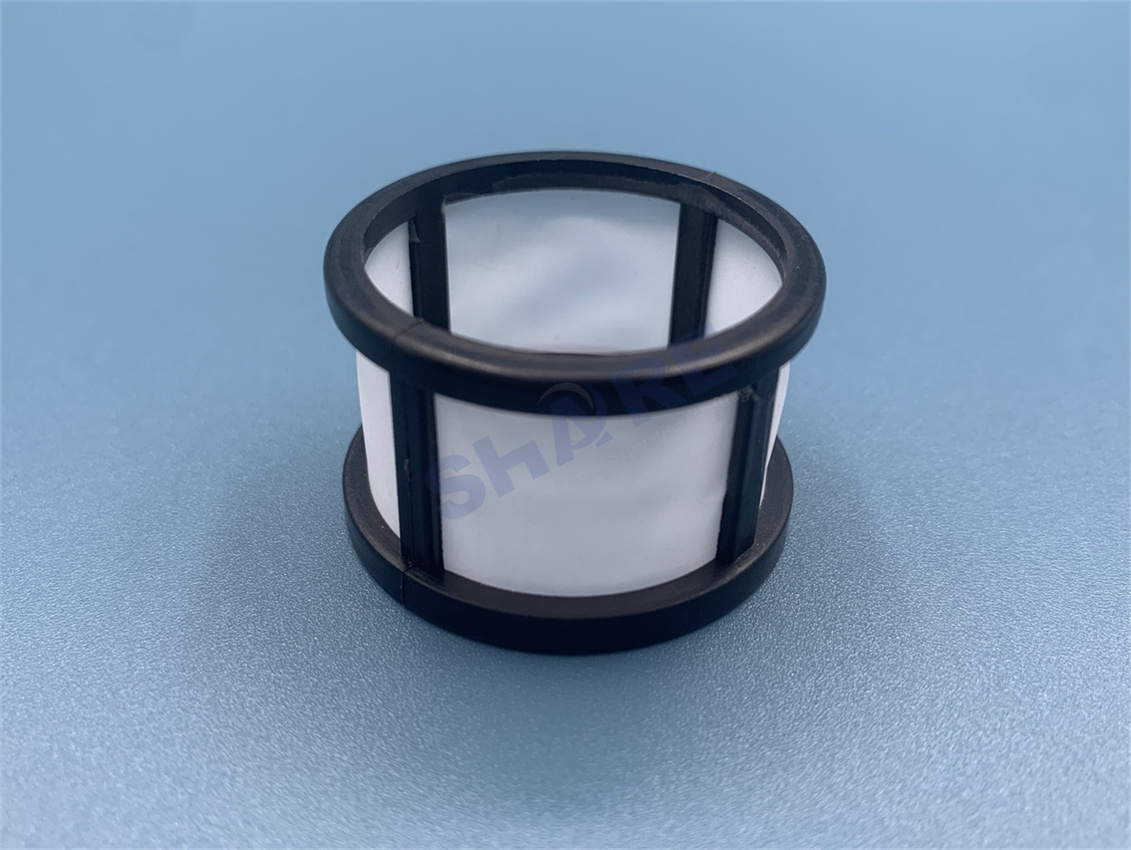

When airborne dust or particles enter the air conditioner or air

cleaner, SHAR polyester mesh filter component is installed to

screen out particles and retain them on the surface of the filter,

thereby protecting the air conditioner.

SHARE's Advantages on Injection Molding

1. Design support

We work closely with our designers and engineers on custom designed

projects to deliver precision filtration solutions.

2. Material selection and sizing

We help customers select the best filtration material to ensure

years of trouble-free operation.

3. Technological advancement

We continuously improve our production facility and products'

performance.

4. Application supports

We have years of experience in design and supply of filtration

products for process and industrial applications.

5. Food safe products

Food and Beverage filtration range meets the requirements of latest

EC directives for food contact.

6. Filter upgrades and retrofits

We provide technical support for filter retrofits and upgrades.

Specification

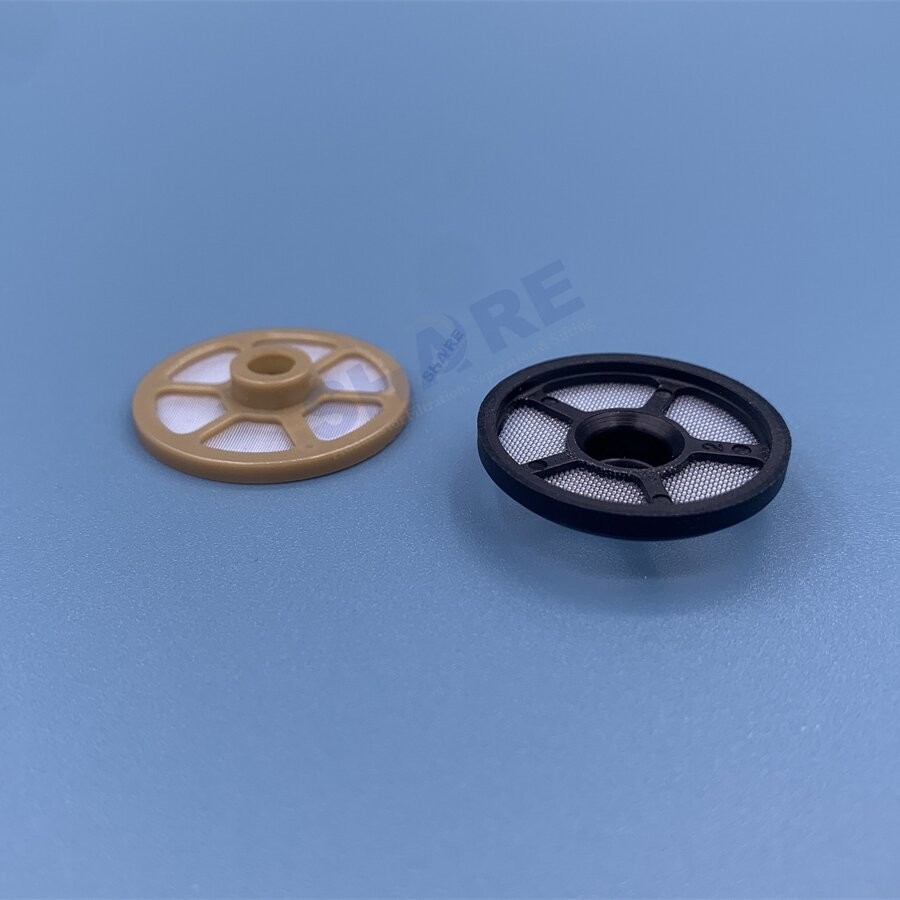

| Item Name | Plastic Molded Polyester Filter Screen Panels for Air Conditioner |

| Manufacturer | Taizhou Share Filters Co., Ltd |

| Brand | SHARE FILTERS |

| Color | As the photo shows or almost all Pantone colors |

| Dimension and Size | Customizable due to customer needs |

| Filter Size | down to 3um, up to 4000um |

| Plastic Materials | PP |

| Filter Materials | Polyester filter mesh |

| Molding Process | Insert/over molding |

| Quality Control | Visual inspection, optical or pressure sensitive equipment and

automated 3D image-inspection equipment, self-inspections, spot

inspections, final inspections |

| Advantages | 1. Many years of application expertise and manufacturing experience

to support customers

(including custom design, material selection, tight tolerance mold

manufacture, rapid prototyping, validation testing and high or low

volume manufacturing)

2. Wide range of molded materials and variety of filter media

available

3. Consistency and quality, reduced cost and maintenance, ease of

installation and replacement

4. Adaptable to any system configuration

5. Long life in aggressive environments

6. Environmentally friendly (fully recyclable) |

| Scope of Applications | Home appliance such as dishwasher filters, washing machine filters, tumble dryer filters,

water filtration, spray and foam nozzles filters, refrigerators

filters, freezers filters, air conditioners filters, water

purifiers, vacuum cleaners filters, hair dryer filters, water and

pool filters, air purifiers. |

Are you ready for a visual feast? Step into the world of Plastic

Filters now!

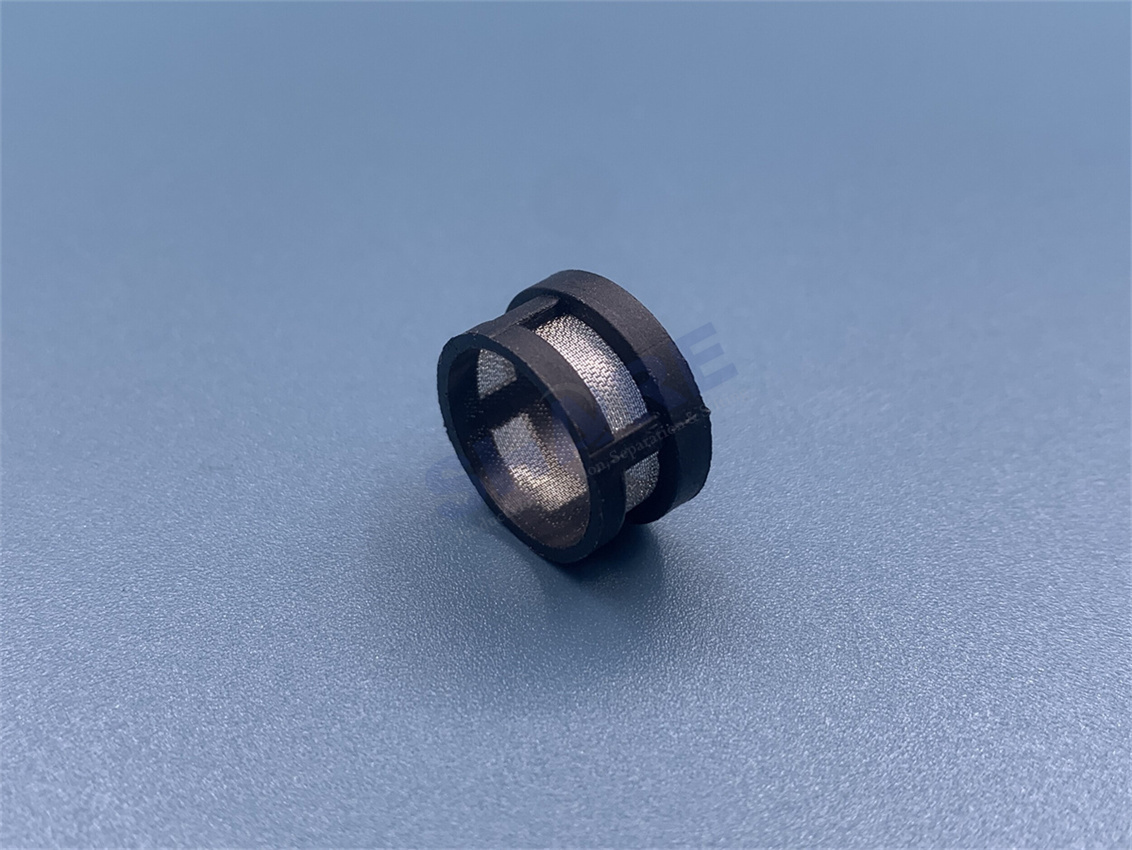

With 40 years experience of mesh weaving technology, precise

injection technology and advanced manufacturing capabilities, SHARE

has designed and manufactured injection molded filters to meet

customer's specific needs for many years.

Our engineers can help customers with their application at every

stage of development, from designing custom filters to choosing the

right materials, making molds with tight tolerances, creating

prototypes quickly, testing to make sure everything works, and

producing filters in both small and large quantities. With our

support, you can have confidence in the quality and performance of

your filters..

Contact us for more application solutions.

Due to the platform's limit on the number of images, reach out to

us to continue enjoying more plastic filters.

Call or email us for more information and support about our

specific customized molded plastic filters for various

applications.

SHARE application specialists with decades of years experiences

will help you select the best solution for your application.

Packaging & Shipping

1. Packed into sealed PE bags, 10pcs to 500pcs/bag according to the

actual size

2. Put into bigger PE bag and then standard export carton

3. Wrapped the outer carton with PE stretch film to prevent damage

during transportation

4. Package belt strengthen if pallets are available

The label contains the following standard information:

item name, manufacturer, material, dimensions, manufacturing date,

order number, batch number etc.

| Port to Port | Door to Door |

| Express(DHL,UPS,FEDEX, EMS) | | 1 - 5 days |

| Air Freight | 1 - 5 days | 4 - 10 days |

| Sea Freight(FCL) | 15 - 30 days | 20 - 35 days |

| Sea Freight(LCL) | 15 - 30 days | 22 - 37 days |

FAQ

1. Where is your factory located? How can I visit there?

We are in Taizhou city, Zhejiang province China. By train, we are

one hour away from Hangzhou and two hours away from Shanghai.

2. Can I get free samples and how long can you deliver them?

We are pleased to provide you with free samples for your

evaluation, which will be sent to you within 2 days. Please feel free to reach out to us for samples.

3. How long does a quotation take?

In most cases, we respond within 2 days. If something in RFQ need be confirmed, we will promptly

notify you soon.

4. How quickly can I get my order finished?

The production lead time is dependent on the quantity. Typically,

it takes 5 to 15 working days for us to complete mass production once you have

placed the order.

5. What about your quality control?

By visual inspection, optical or pressure sensitive equipment and

automated 3D image-inspection equipment, our production operators

conduct self-inspections at every stage of the process.

Additionally, we have spot inspections and final inspections

carried out by our Quality Control (QC) team.

6. What's your largest advantage?

One of our core competencies is our excellent converting

capabilities from yarn over weaving to converted items with

professional technical team and quality guarantee and management

for more than 30 years.

7. What kind of payment terms do you accept?

T/T and LC and more.