We specialize in designing and developing various filter components

for household appliances, such as dishwasher filters, washing

machine filters, tumble dryer filters, water filtration, spray and

foam nozzles filters, refrigerators filters, freezers filters, air

conditioners filters, water purifiers, vacuum cleaners filters,

hair dryer filters, water and pool filters, air purifiers.

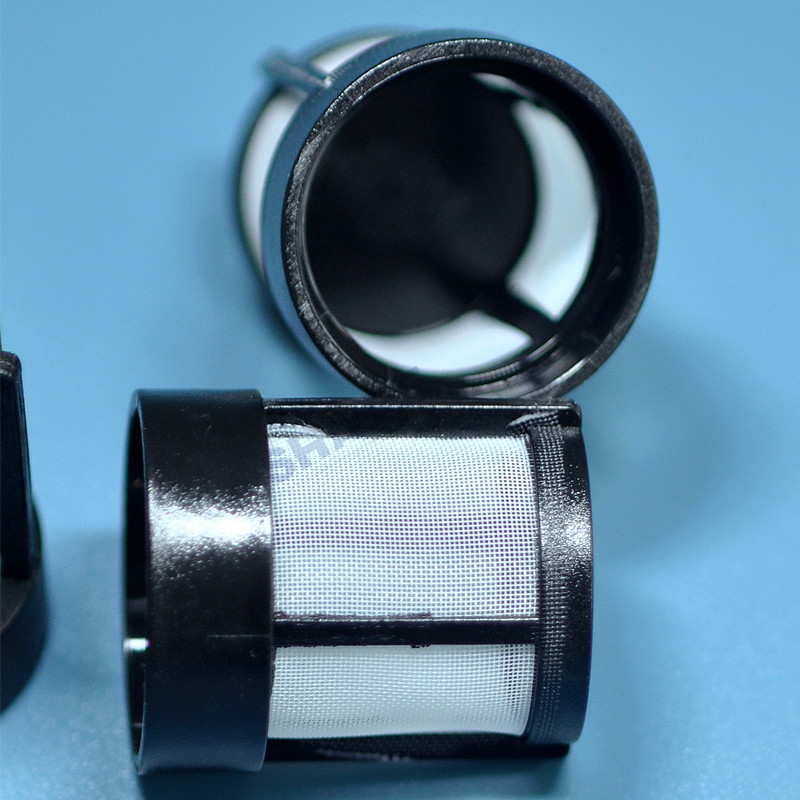

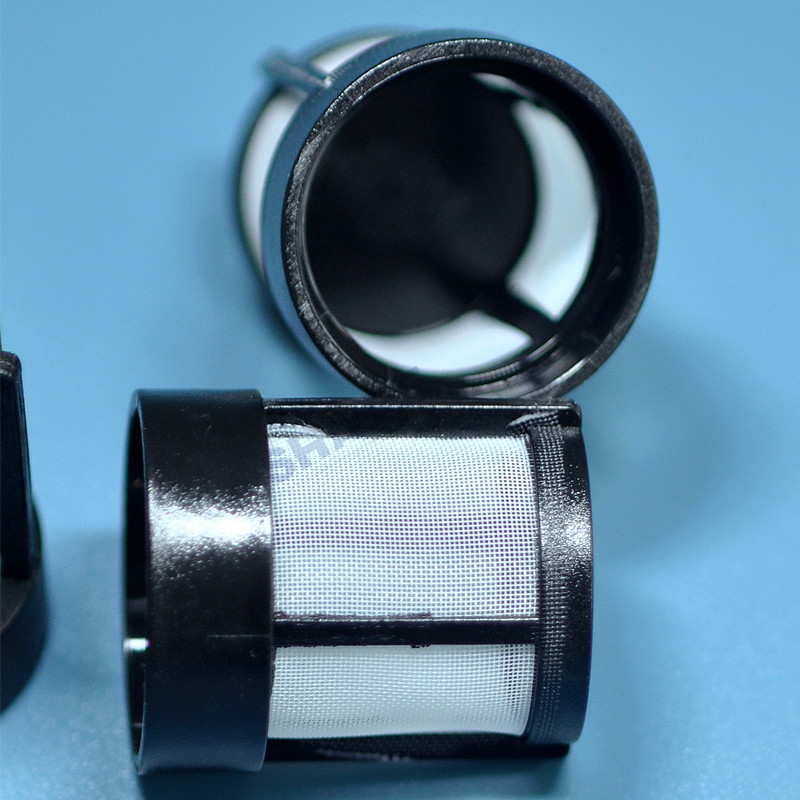

Whole House Spin Down Sediment Water Screen Filter Element

For your homes plumbing, kitchen and bathroom fixtures from

damaging particles found in city or well water responsible for

clogging faucets, shower heads, water appliances such as water

heaters, washing machines, water purifiers, and other water-related

equipment.

SHARE sediment water filters element are ideal frontier water

filter in whole house water filter system, protecting your entire

plumbing system from sediment, rust, dirt, sand, and large

particles.

Mesh Filters from 50 to 500 microns(commonly 80 100 130 200 300 500 microns) are available on demand. Our application specialist will advise

the best filtration solutions including materials, micro ratings

and desingns for you according to our many years of experiences and

expertise.

Contact us for mesh filter tube replacement in different size.

SHARE has more than 50 sets of vertical and horizontal automatic plastic injection molding machine

to fulfil customer and market needs for general and specific

filtration solutions. Our molded filters are usually made of various types of plastics

and meshes.

Our molded filters are long lasting, lightweight and corrosion

resistant, often used in home appliance, food industry, water

filtration, automotives and medical applications.

Customers trust SHARE filtration solutions for customization, full

traceability, consistent reliable performance and lot-to-lot

accuracy. We help customers with their application at every stage of

development to make sure quality filter mesh components at

competitive price with fast delivery.

| Item Name | Share Filters Customized Sediment Mesh Screen Filter |

| Manufacturer | Taizhou Share Filters Co., Ltd |

| Brand | SHARE FILTERS |

| Color | As the photo shows or almost all Pantone colors |

| Dimension and Size | Customizable due to customer needs |

| Micron Rating | 50 to 500 microns(commonly 80 100 130 200 300 500 microns) |

| Plastic Materials | ABS, PC/ABS, PP, PC, POM, Nylon 6, Nylon 66 with or without fiberglass reinforcement etc. |

| Filter Materials | Nylon (polyamide) filter mesh, polyester filter mesh, polyethylene

filter mesh, polypropylene filter mesh, stainless steel filter

mesh, brass filter mesh |

| Molding Process | Insert molding |

| Quality Control | Visual inspection, optical or pressure sensitive equipment and

automated 3D image-inspection equipment, self-inspections, spot

inspections, final inspections |

| Advantages | 1. Many years of application expertise and manufacturing experience

to support customers

(including custom design, material selection, tight tolerance mold

manufacture, rapid prototyping, validation testing and high or low

volume manufacturing)

2. Wide range of molded materials and variety of filter media

available

3. Consistency and quality, reduced cost and maintenance, ease of

installation and replacement

4. Adaptable to any system configuration

5. Long life in aggressive environments

6. Environmentally friendly (fully recyclable) |

| Scope of Applications | Home appliance such as dishwasher filters, washing machine filters, tumble dryer filters,

water filtration, spray and foam nozzles filters, refrigerators

filters, freezers filters, air conditioners filters, water

purifiers, vacuum cleaners filters, hair dryer filters, water and

pool filters, air purifiers. |

Filter Material Selection

Filter material slection is crucial to the performance of the final

filters.

At SHARE, we produce filter materials characterized by precise mesh openings, open area and mesh

thickness by ourselves. The most commonly used filter material for

plastic filters are the following:

Polyamide mesh (Nylon): Resistance to acids is limited and dependent on the concentration

and temperature. Excellent resistance to alkalis, including caustic

soda and caustic potash. Chemical performance against organic

solvents is very good. Temperature resistant from 0 to 130 °C when

dry, 95 to 100 °C in water.

Polyester mesh: Resistant to most acids. Not resistant to alkalis. Temperature

resistant from -75 to +150 °C (for short periods), up to 125 °C for

longer requirements.

PP mesh: Humidity resolution at 95% rel. air moisture and 25 °C is less

than 0,01%. Resistant to alkalis, even in high concentrations. Use

with organic solvents is limited. Temperature resistant from 0 to

+150 °C (for short periods), up to 125 °C for longer requirements.

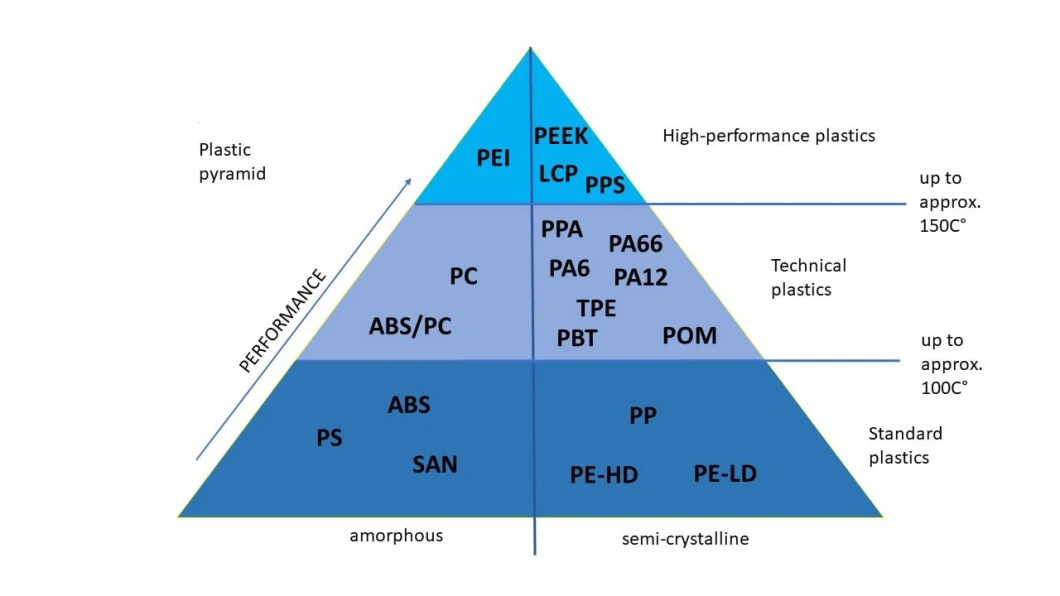

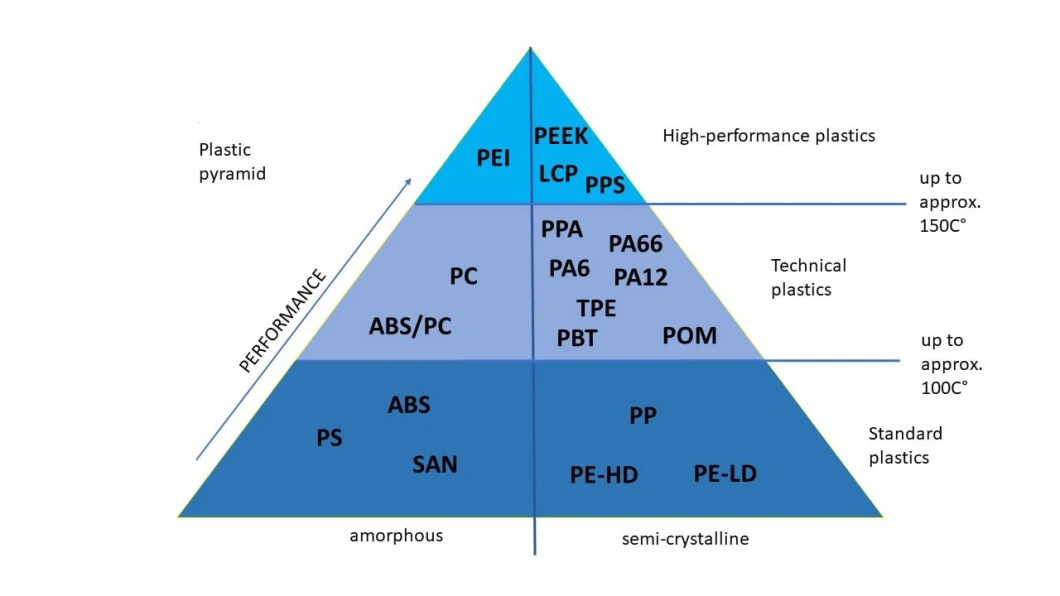

The application and the requirements for the plastic part are

decisive before injection molding. The most often used plastic we

select are including PE, PP, ABS, PC, POM, PBT, PA, PPA to PEEK.

Material property is an important know-how to injection molding. It

is highly related with molding quality, finish and cost. Our team devote this knowledge and experience to the molding

products of our customers. From various thermoplastic (PA, PP, PC,

POM, PET, ABS and Peek) to thermosetting (PE, Epoxy and Silicon)

even combined plastic materials (such as glass fiber), we put

material property as a must-evaluation when design tooling, so we

would also help to suggest equivalent materials for quality

improvement or cost reduction.

The first step in making injection molded products is creating the

molds(moulds). The accuracy of these molds is critical because it

directly affects the quality of the final products. Here's how we

make our molds:

1. We start by examining the product drawings.

2. Then, we create a "Design for Manufacturability" report (DFM).

3. Next, we use mold flow analysis to plan the mold's design.

4. We create detailed tooling drawings.

5. Finally, we make the mold.

Once the mold is ready, we produce a few test samples to check if

they meet the right dimensions. If they do, we send these samples

to customers for their approval. If there are any issues, we adjust

the mold or the production settings and make new samples for

testing.

After our customer approves the samples, we move on to purchasing

raw materials and quality checks. Then, we mix materials, do the

molding, and trim the products, with multiple quality checks along

the way. Finally, we assemble and package the order. Once

everything is ready, we share a packing list with customers to

coordinate shipments.

Established in 1983, Taizhou Share Filters Co. Ltd. has been

specializing in the production of precision monofilament and

multifilament filter fabrics and filter components in polyamide,

polyester, polypropylene, polyethylene and metallic mesh.

With 40 years of expertise and experience from precision filter

mesh materials to filter components, SHARE has the capability to

tailor our products to your exact application through our

outstanding manufacturing capabilities and automated fabrication processes(cutting, calendering, welding,

slitting, sewing, pleating, molding, and more).

Our filter products are used in a wide range of different

filtration fields such as indrustrial and home appliance, automotive, irrigation, hydraulic, medical and

health, food and beverage, electronics and aerospace, along with many other industrial applications.

By vertical integration of our global supply chain and expertise,

our extensive manufacturing and production facilities, our

experiences of filtration team, as well as our materials

management, we take end-to-end control of all the steps in the

manufacturing process, including weaving, fabrication, molding. Our

ability to efficiently manufacture products not only ensures

repeatable product quality, but also maintains a steady supply

chain, reduces production costs and shortens lead times for our

customers.

Whether you want to improve the quality or reduce the cost of your

existing filter component, plan a new filtration application, or

need assistance with specifications and design validation, SHARE is

here for you. Our specialist problem solving skills are ready to

address any challenges you encounter.

When we receive your your print, specification, drawing, sample or application

environment, our experienced sales and application engineers will

assess and customize plastic filters step by step according to the

information you provided. Before we start to produce your molded

filters, the main factors we consider are as follows:

1. Mesh size or the size of the particle you need to filter

2. Mesh material and housing material (consider the working

condition)

3. Mesh thread diameter, mesh thickness, opening area

4. Chemical compatibility: housing and filter mesh, caustic,

acidic, organic solvent etc.

5. Operating conditions: temperature, pressure drop, flow etc.

6. Physical connections: for easy installation and replacement

We aim to offer the most reliable and cost effective filter

solutions for all filtration applications. SHARE application speciallists with decades of years experiences

will help you select the best filter solution for your application.

Contact SHARE today for additional information and how we can help

you with your specific filtration requirements.

1. Packed into sealed PE bags, 10pcs to 500pcs/bag according to the

actual size, double bagged and the product label is attached in the

inner bag

2. Put into bigger PE bag and then standard export carton

3. Wrapped the outer carton with PE stretch film to prevent damage

during transportation

4. Package belt strengthen if pallets are available

The label contains the following standard information:

item name, manufacturer, material, dimensions, manufacturing date,

order number, batch number etc.

| Port to Port | Door to Door |

| Express(DHL, UPS, FEDEX, EMS) | | 1 - 5 days |

| Air Freight | 1 - 5 days | 4 - 10 days |

| Sea Freight(FCL) | 15 - 30 days | 20 - 35 days |

| Sea Freight(LCL) | 15 - 30 days | 22 - 37 days |

1. Where is your factory located? How can I visit there?

We are in Taizhou city, Zhejiang province China. By train, we are

one hour away from Hangzhou and two hours away from Shanghai.

2. Can I get free samples and how long can you deliver them?

We are pleased to provide you with free samples for your

evaluation, which will be sent to you within 2 days. Please feel free to reach out to us for samples.

3. How long does a quotation take?

In most cases, we respond within 2 days. If something in RFQ need be confirmed, we will promptly

notify you soon.

4. How quickly can I get my order finished?

The production lead time is dependent on the quantity. Typically,

it takes 5 to 15 working days for us to complete mass production once you have

placed the order.

5. What about your quality control?

By visual inspection, optical or pressure sensitive equipment and

automated 3D image-inspection equipment, our production operators

conduct self-inspections at every stage of the process.

Additionally, we have spot inspections and final inspections

carried out by our Quality Control (QC) team.

6. What's your largest advantage?

One of our core competencies is our excellent converting

capabilities from yarn over weaving to converted items with

professional technical team and quality guarantee and management

for more than 30 years.

7. What kind of payment terms do you accept?

T/T and LC and more.